Product Hub October 28, 2020

The Making of a Unique Promo Product

Find out how one supplier brought a high-end product to life.

What does it take to create a unique promo product? Ask California-based Origaudio. Led by founders Jason Lucash and Mike Szymczak, the company – now part of Top 40 supplier HPG (asi/61966) after being acquired last year – has distinguished itself since its 2009 founding through its product design of electronics and tech accessories, among others.

“I absolutely love designing and innovating within the promo industry, and I love the challenges that come with it,” says Lucash, whose company has been honored with multiple Counselor Product Design Awards. “It was revolutionary when we built the Boxanne speaker six years ago and changed the way speakers were designed and sold in the industry. Every year we raise the bar for our new product launches.”

Origaudio’s Jason Lucash on a trend-hunting trip to Japan.

In most years, Lucash and his team take trend-hunter retail trips to Asia, especially Japan, as well as across the United States, finding inspiration for new products. Because of the pandemic, those jaunts have been on hold, but Lucash still searches using digital means, on sites like Dieline (for packaging ideas), TechCrunch and Inspiration Grid, as well as the Instagram feeds of leading design companies like Shinola and Allbirds.

Back in 2018, way before anyone had heard of COVID-19, Lucash vacationed in the Montana mountains and returned with an idea for an upcoming product collection. It came to be known as Finley Mill, an assemblage of high-end outdoor products that Origaudio unveiled last year. “Since it was our 10-year anniversary launch, I wanted every aspect of the collection to be perfect and reflect my personal design style and taste,” Lucash says. “I think we nailed it.”

But “nailing it” takes time – months of brainstorming, designing and sampling, with coordination between team members, vendors and factories, all to create the newest product that distributors will be excited to sell. Here, Lucash and Origaudio reveal the process behind the creation of the distinctive Finley Mill Pack, from inspiration all the way to the finished product.

The Finley Mill Pack is the centerpiece of Origaudio’s Finley Mill Collection of high-end, hipster-inspired outdoor products released in celebration of the supplier’s 10th anniversary.

STEP 1

Discovering a Spark of Inspiration

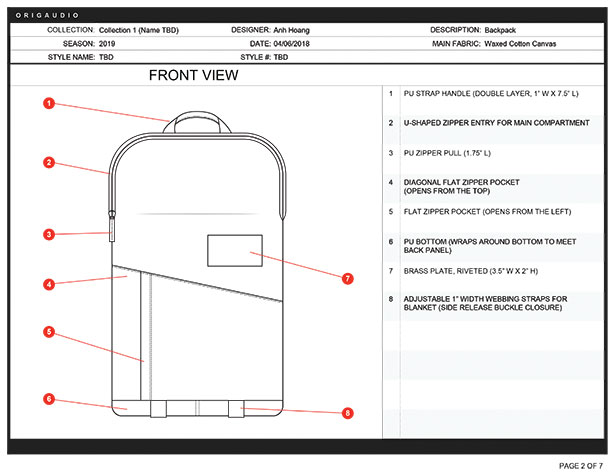

Almost three years ago, Lucash took some well-deserved R&R at a luxury ranch resort in Montana and received a unique gift during his stay: a heavy-duty work apron made of olive-green wax canvas with leather trim. He was impressed with the quality, feel and overall aesthetic. It just so happened that, upon returning to his California offices, he’d be planning out a special 10-year collection for Origaudio.

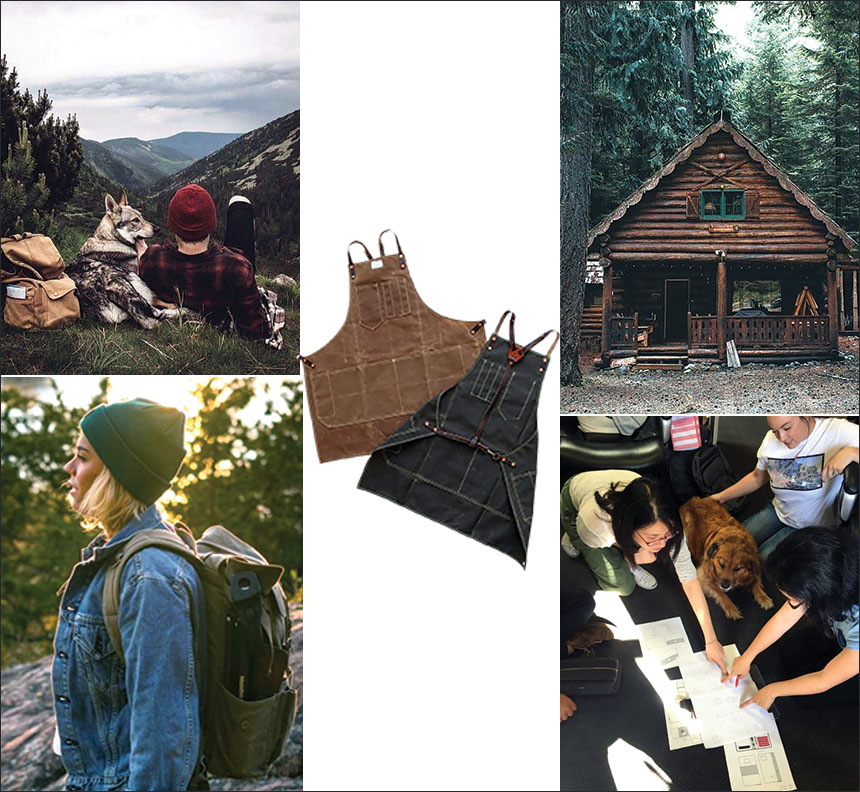

“I thought, ‘Let’s build it around this apron,’” he says. “I looked at Filson, a high-end outdoor products brand, for inspiration. It reflects my personal aesthetic. I like spending time outdoors, but at bougie dude ranches or in Napa. It’s a hipster, high-end collection.”

STEP 2

Considering the Potential Audience

With the apron as the starting point, the Origaudio team brainstormed about what a target audience for this new collection would look like: “Millennials making six figures, who spend weekends in A-frame cabins and take day hikes,” says Lucash.

The staffers (shown above) then put together design boards for inspiration. “The images (shown above) embody the feel and target consumer we’re going after,” says Lucash. “They actually sit in our office next to our designers when they’re building the tech packs. Then, after the items are approved for mass production, the boards are passed off to marketing and creative so they can base the digital and physical assets off the inspirational images.”

STEP 3

Designing the Products

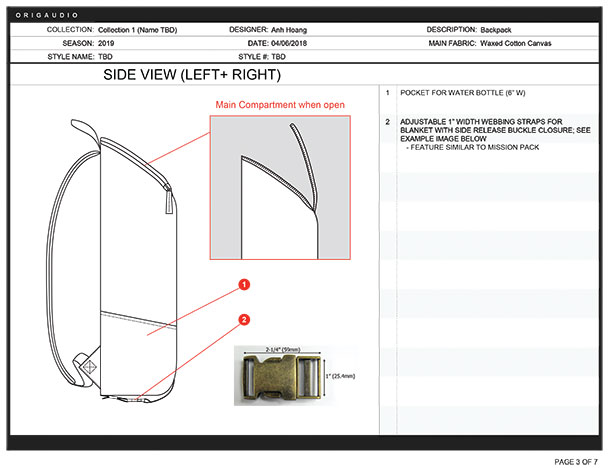

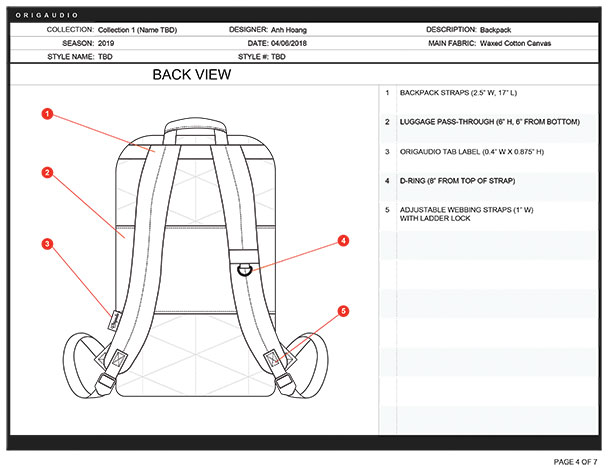

Lucash and his team of creatives worked on brainstorming, designing the tech packs (which include specs and line drawings) and approving prototypes for the next several months. They decided to lead with the Finley Mill Pack, a backpack in a color and fabric that echoed the work apron, with similar leather trim and brass accents.

“I picked out brass hardware for the bag because I thought the green/brown/gold color palette was on point,” says Lucash, who spent time in marketing at leading backpack brand JanSport before founding Origaudio. “I wanted it to have a rustic feel (like the under-looping carry straps that can be found on backpacks from decades ago) with a current-day twist.”

A designer at Origaudio put together the technical drawings (shown above), and Lucash made edits before submitting them to the factory for different design samples. At the same time, the Origaudio team was working on additional items for the early 2019 launch of Finley Mill, including bags, blankets, stationery sets, keychains, a multi-tool, “Stashlight” and more, all created for the day hiker.

STEP 4

Finding the Right Factories

After the team settled on its first dozen products, Origaudio started reaching out to factories to help them develop the items. It was here that the apron that started it all made its final contribution. “It doesn’t exist anymore,” says Lucash. “We cut it up and sent swatches to the different factories.”

The supplier partnered with a bag factory in China, which began developing prototypes based on the tech pack and swatches. “For the first samples, the factory uses the fabrics they have around so we can get the structure and shape,” says Lucash. “Then they create it out of the actual materials, we make adjustments and sign off on the final one.” While the standard process includes three sample rounds, each one handmade from patterns, this one required six to perfect the bag’s hardware.

Lucash visits with his team at the overseas factory that played a starring role in bringing the Finley Mill Pack to the promo industry.

Finally, Lucash approved “the golden sample” which would be the model for the mass-production quality of the bag. “One sample stayed with me, the other stayed with the factory so the proper checks and balances were in place,” he says.

All the bags were made at the same overseas factory, but in all, Lucash says they worked with 10 different manufacturers for the items that make up the complete collection. “That’s a lot,” he says. “There were the bags, the blanket, the brass. The soap was milled in Montana. The Eureka Kit was sourced separately. It was driving our vendor relations person crazy. And of the 10 factories, eight were new partners for us. That was tough because we’re trying to establish a relationship while getting the products designed.”

STEP 5

Releasing the Product to the World

Origaudio sent out initial POs for Finley Mill products in mid-August 2018, at about the same time HPG acquired Origaudio, and the first 12 items made their public debut at ASI Orlando the following January after almost a year of development.

“Hearing and seeing customers’ reaction, we felt such a sense of accomplishment and happiness,” says Lucash. “We devoted over a year to build this collection and it was the main focal point of our branding and product launch strategy for the year.”

Lucash says the collection, which now includes 20 items, has sold well with distributor partners. “For 2021, we’ll take the same approach for building products and the bar will continue to be raised, even if the world landscape has changed,” he says. “We’ll adapt, innovate and move forward just as we always have.”

Sara Lavenduski is senior editor for Advantages. Tweet: @SaraLav_ASI; email: slavenduski@asicentral.com

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.