Product Hub February 01, 2021

Show Report: Impressions Connect

Impressions Connect, formerly known as ISS, was held virtually from Jan. 25 to 29 for decorated-apparel professionals.

Impressions Connect, a virtual trade show held from Jan. 25 to 29, incorporated 28 exhibitors and more than 50 educational sessions for decorated-apparel professionals. Previously known as ISS, the Impressions Expo, owned and operated by Emerald Expositions, still has dates scheduled for three in-person events this year: Long Beach, CA, in April, Atlantic City, NJ, in June and Fort Worth, TX, in September. But for those unable or unwilling to travel, the virtual show had a lot to offer.

Several exhibitors at this year’s online event noted that although they still prefer a traditional, in-person event, a virtual show is an important touchpoint with customers and actually offers a few perks. “One is the cost to attend – often virtual shows come at little or no cost to the attendee,” said John Lindgren, trade show director for Top 40 supplier SanMar (asi/84863), one of the suppliers exhibiting at the show. “Another is that an attendee can often have more control over their own schedule since they aren’t having to travel.”

Both of those factors also mean that exhibitors get a chance to meet with “a broader range of people,” said Tim Check, product manager at equipment manufacturer Epson America. At a live show, it’s typically only the higher-ups at a company able to attend; with virtual, on-the-ground employees – the ones actually operating shop equipment – have the opportunity to connect with vendors too.

Apparel suppliers and equipment manufacturers showcased a wide range of products in their online booths. Here are a few of the standout trends.

1. Inspired by Tie-Dye

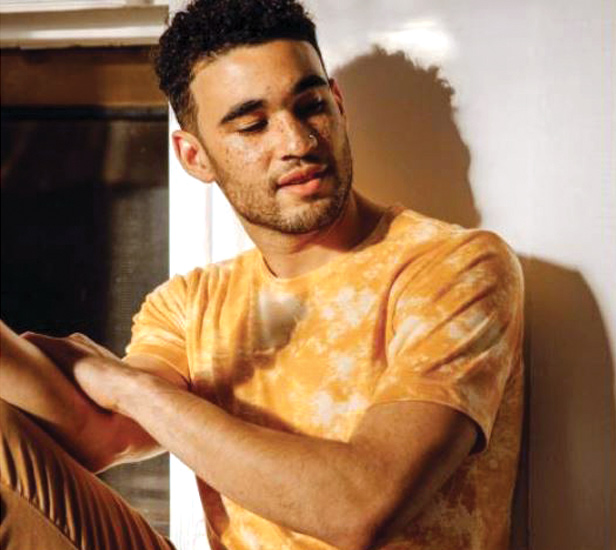

The Go-To Tee (1070CB) from Alternative Apparel, part of Brandwear United.

Tie-dye has been a huge trend the last few years, and was particularly hot in 2020 as homebound fashionistas looked for DIY activities to occupy their time during COVID. Several apparel suppliers had tie-dye and tie-dye inspired items on display in their booths. Alternative Apparel, part of Brandwear United (asi/59528, previously HanesBrands), added four new tie-dye colors – gray, blue, pink and gold – to its Go-To Tee (1070CB). Though it’s a print, rather than a true tie-dye, it still looks like the real thing because it’s not a repeating pattern, said Lynn Decker, a key account executive with Brandwear United. “We’ve gotten a great response to it so far,” she added.

Gildan (asi/56842) was showing off a new pigment-dying technique for its Comfort Colors line, also inspired by tie-dye. Called Color Blast, the effect is created by blasting a T-shirt (1545) or fleece (1745) with color, rather than immersing it in pigment, giving each garment a unique, individualized look.

2. Made to Be Decorated

SanMar’s new Perfect Tri DTG Tee (DM130DTG) is pretreated all over to make decoration easier.

For apparel decorators, one of the most important aspects of a blank garment is how easy it is to embellish, and suppliers are always looking for ways to innovate in this arena. SanMar was showcasing the new Perfect Tri DTG Tee (DM130DTG) from its District brand. The garment employs a proprietary technology that pretreats it on the inside and outside, front, back and sleeves – meaning it’s ready for direct-to-garment printing right out of the box.

The new style “changes the DTG game by allowing customers to print faster, cleaner and more efficiently without the need for traditional pretreatment steps,” said Rob Crowley, senior director of product at SanMar. “Most importantly, our unique pretreatment technology is odorless and doesn’t affect the exceptionally soft hand-feel our Perfect Tri Tee is known for.”

Bella + Canvas (asi/39590) showed off garments made with its Airlume combed and ringspun cotton and eco-friendly dying process. The ringspun technique makes it “the best blank canvas for printing,” according to the supplier.

3. Sublimation Starter Kit

The SureColor F170 from Epson is an 8.5-inch-wide desktop sublimation printer.

In addition to showing more production-heavy, higher-end digital printing technology, Epson America also went small format, with a true desktop dye sublimation printer. Retailing for just $400, the 8.5-inch-wide printer is great for businesses or crafters who’ve always wanted to try the dye sublimation but don’t want to make a huge investment to start out, Check said.

“It’s really exciting seeing how these printers are starting to change things,” he added. “People are doing a lot of new startup businesses. … This is their engine to do that.”

The SureColor F170 is big enough to allow decoration of coffee mugs, wine tumblers and even crew socks. The printer could be a gateway to buying more scalable equipment down the line, or even partnering with a contract decorator to handle larger orders that come in, Check said.

4. Getting Heat

The GoccoPro QS 2536 from Xpresscreen is a thermal screen-making machine.

Jay Doub of Xpresscreen ran several product demos via Zoom to show off the equipment supplier’s thermal screen making technology. The GoccoPro QS 2536 enables screen printers to turn the tricky process of making a halftone screen into “a one-touch operation,” Doub said. The machine is also less messy and requires less space. “It’s heat-sensitive, not light-sensitive,” he said. “It doesn’t need a dark room.” The computer to screen (CTS) system uses a thermal head that heat-perforates a screen master of mesh laminated with film.

The technology also is more eco-friendly than conventional screen-making methods, according to Xpresscreen, since it uses no emulsions or chemicals and thus generates no wastewater. It’s also a big time-saver. Creating a screen from start to finish with the GoccoPro takes about 10 minutes, versus several hours using conventional methods, according to the company.

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.