Strategy May 14, 2024

Decorating Roundup: Stahls’ Now Offers Contract Decorating Services

Plus, Penn Emblem received an innovation award, and Vastex released an adjustable dryer exhaust.

Stahls’ (asi/88984) has introduced contract decorating services for apparel and headwear, to help distributors and decorators with overflow production needs or incoming requests that are out of their in-house capabilities.

Stahls’ (asi/88984) now offers contract decorating services for apparel and headwear.

The heat-printing consumables and equipment supplier based in St. Clair Shores, MI, notes that it has over 90 years of printing expertise and innovation. Existing businesses can now use Stahls’ fulfillment for UltraColorMAX direct-to-film (DTF) transfers or emblem and patch orders, by ordering blanks from integrated catalogs from Top 40 suppliers SanMar (asi/84863), S&S Activewear (asi/84358) and alphabroder (asi/34063), then assigning custom transfers from their Stahls’ account and scheduling fulfillment for drop-shipping.

Users must have an active Stahls’ account with a valid tax-exemption certificate on file to be eligible for apparel and headwear fulfillment services.

Penn Emblem Awarded for Emblem Honoring Veterans

The NAUMD awarded Penn Emblem (asi/77120) an innovation award for this badge created for the U.S. Department of Veteran Affairs.

Trevose, PA-based Penn Emblem Company (asi/77120) won an innovation award for decoration from the National Association of Uniform Manufacturers & Distributors (NAUMD) for a Made-in-the-USA badge it created for the U.S. Department of Veteran Affairs.

The supplier used one of its PennFlex badges, a thermoplastic emblem that has a 3D effect and includes customization options such as a matte or metallic finish. The NAUMD called the emblem a “visually striking design” and praised its “precise details seen in the eagle wings and rope border,” noting also that “the flags have subtle contrasting textures that take the viewers’ eyes from a smooth flat base of stars to elegant, waved ripples in the stripes.”

Penn Emblem emphasized that the award was the result of a team effort, and that it was an honor to be chosen for the NAUMD’s innovation award.

Vastex Boosts Efficiency & Safety With Adjustable Dryer Exhaust

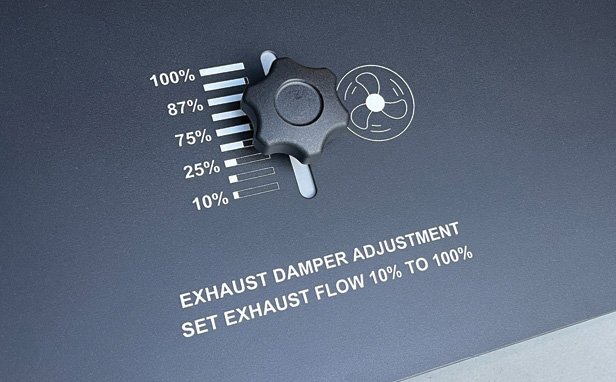

Vastex International has added an adjustable dryer exhaust to its EconoRed conveyor dryers.

Bethlehem, PA-based Vastex International has announced that its EconoRed conveyor dryers are now equipped standard with an adjustable exhaust for optimizing the curing of printed textiles and films, while cooling the skin of the enclosure and minimizing wasted heat.

Using a damper-control knob, the user can adjust the volume of exhausted air from 100% to 10% to remove all fumes emitted in the heating chamber according to the size, weight, throughput and ink type of DTG and screen-printed garments and/or the dwell time needed to cure powdered adhesives on DTF images or screen-printed transfers, according to the company. Excess air flow is diverted and filtered to cool the double-wall skin of the heating chamber for worker safety.

“A wide range of variables determines the amount of exhaust air needed for any given run, from high-capacity evaporation and curing of water-based pretreatment and DTG-printed inks, to powdered DTF adhesive and screen-printed transfer films that off-gas significantly yet must be prevented from lifting off the conveyor belt due to high volumes of exhausted air,” said Mark Vasilantone, Vastex president.

Together with digital control of heater temperatures in one-degree increments and variable belt speeds, the adjustable exhaust allows operators to fine-tune drying parameters on a job-to-job basis, while accommodating the differing exhaust requirements of systems having multiple heating chambers, according to Vastex.

Retrofit kits will be available for upgrading existing EconoRed dryers with adjustable exhausts.

Ryonet Unveils Riley Hopkins 360 Screen-Printing Press

Ryonet now offers a line of Riley Hopkins 360 manual screen-printing presses, including this eight-color, six-station unit.

Ryonet, a Vancouver, WA-based screen-printing equipment and supply company, has introduced the Riley Hopkins 360 manual screen-printing press, with features that it says cater to both manual and automatic print shops.

Among the features is XYZ spring-loaded micro registration, which allows for pinpoint alignment adjustments and is designed to reduce setup times and enhance print quality. The Riley Hopkins 360 provides options for either side or back clamps; side clamps offer increased stability, while back clamps allow for greater flexibility. In addition, the manual press integrates seamlessly with ROQ automatic systems, facilitating an easy transition from manual to automatic modes. The press comes with a limited lifetime warranty on all non-wear parts.