In early February, Wearables sent screen-printing consultant Charlie Taublieb to Valparaiso, IN, for two days to teach the staff of Blythe's Athletics some new techniques and help them streamline their production workflow. The intensive coaching session left owner Mike Blythe full of excitement and new ideas for his business.

We'll be checking back in with Blythe periodically to find out how many of Taublieb's suggestions have been implemented by the shop. The full story of Blythe's Athletics' "Extreme Screen-Printing Shop Makeover" will appear in the June issue of Wearables. In the meantime, check out this slideshow from Taublieb's trip to Indiana.

Blythe's Athletics in Valparaiso, IN, is a family-owned screen-printing shop, started in the 1950s. The shop has doubled in size in the last five years, growing from 10 employees to 28. However, managers have struggled with scheduling, employees make mistakes that cause production to lag, and no one has time to try out new printing techniques. "We need help from the outside world," says owner Mike Blythe.

Enter Charlie Taublieb, a longtime consultant who travels the world helping screen-printing shops of all sizes improve quality and streamline production. Blythe's Athletics, the winner of the Wearables Extreme Screen-Printing Shop Makeover, had the benefit of two days of Taublieb's undivided attention in early February.

Taublieb brought a suitcase full of goodies to share with staff at Blythe's, including an array of inks and foils for the them to sample.

Here, Taublieb talks shop with Blythe (center) and screen printers Connie Hogge and Jessica Walker (far right).

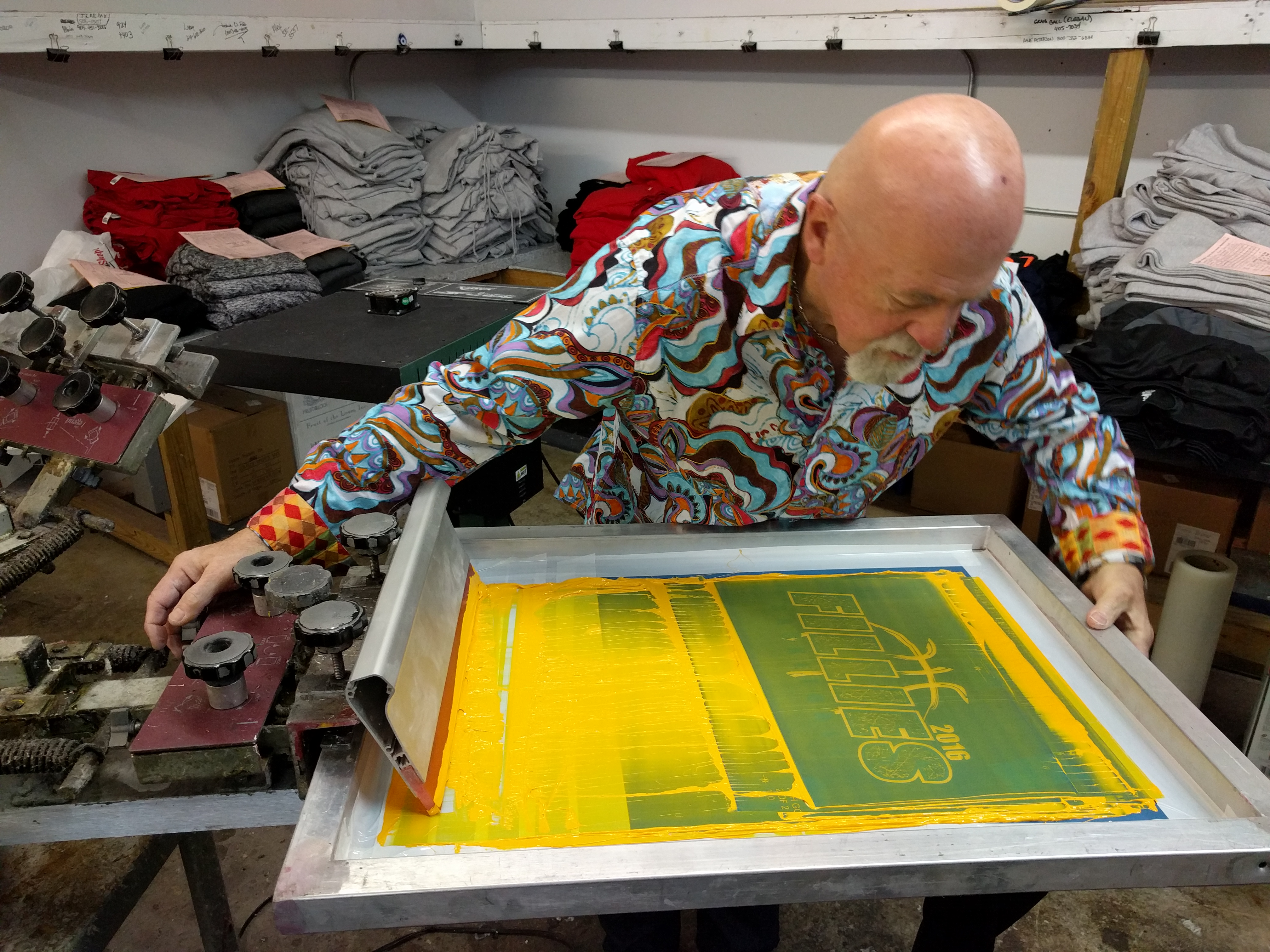

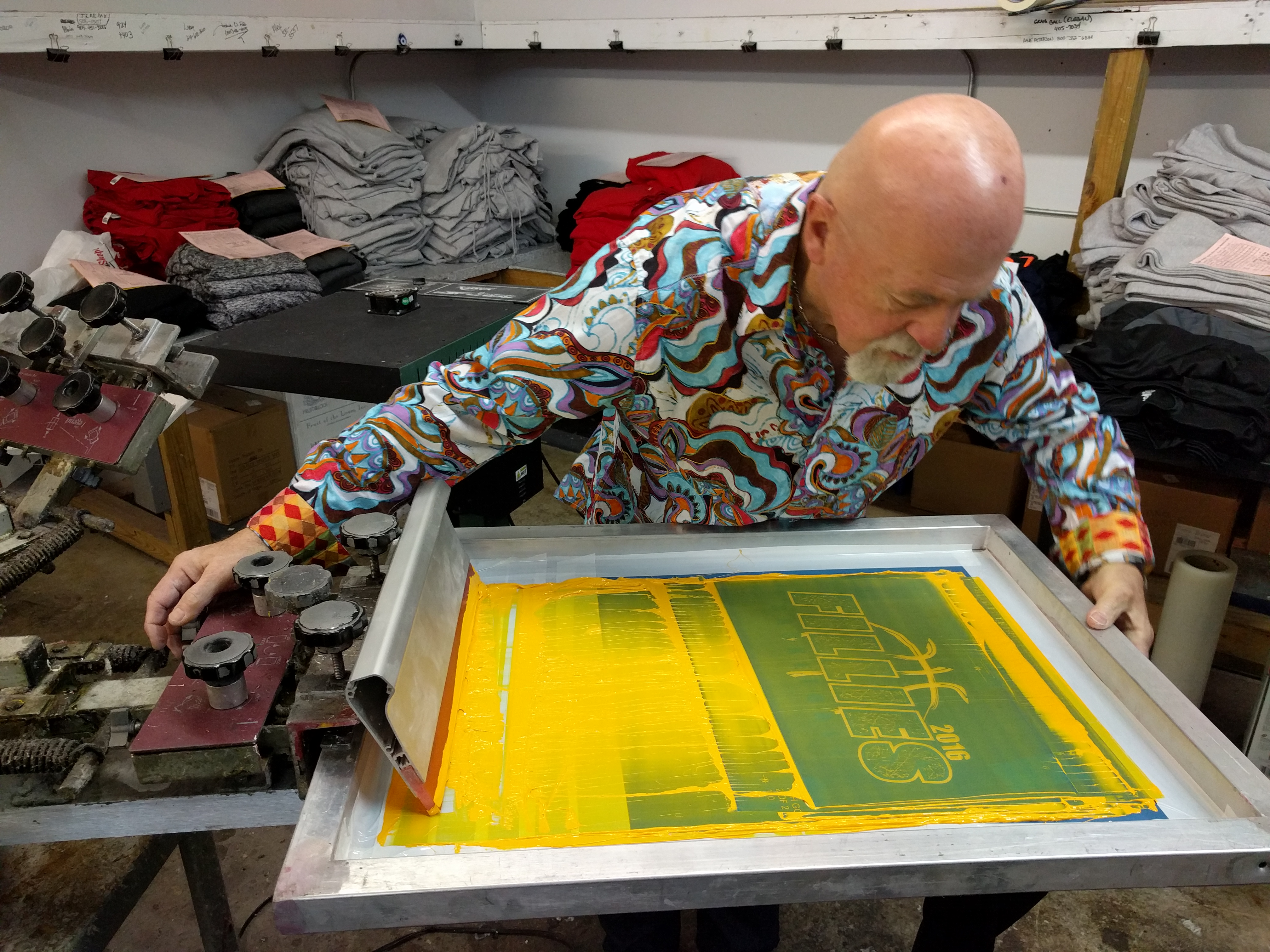

Taublieb checks registration of a screen at Blythe's Athletics. Getting prints in perfect registration is one of the areas the shop has struggled with in the past.

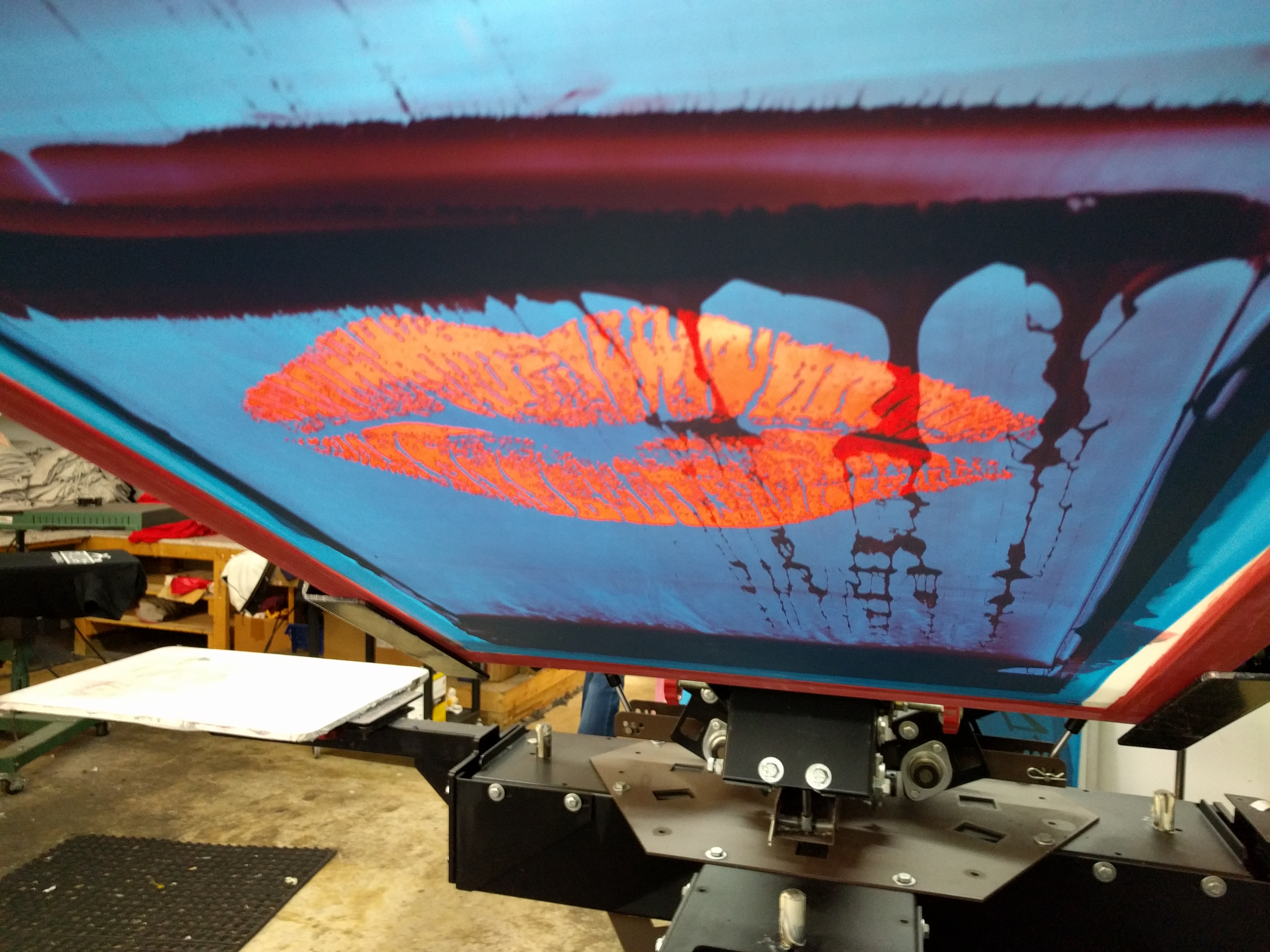

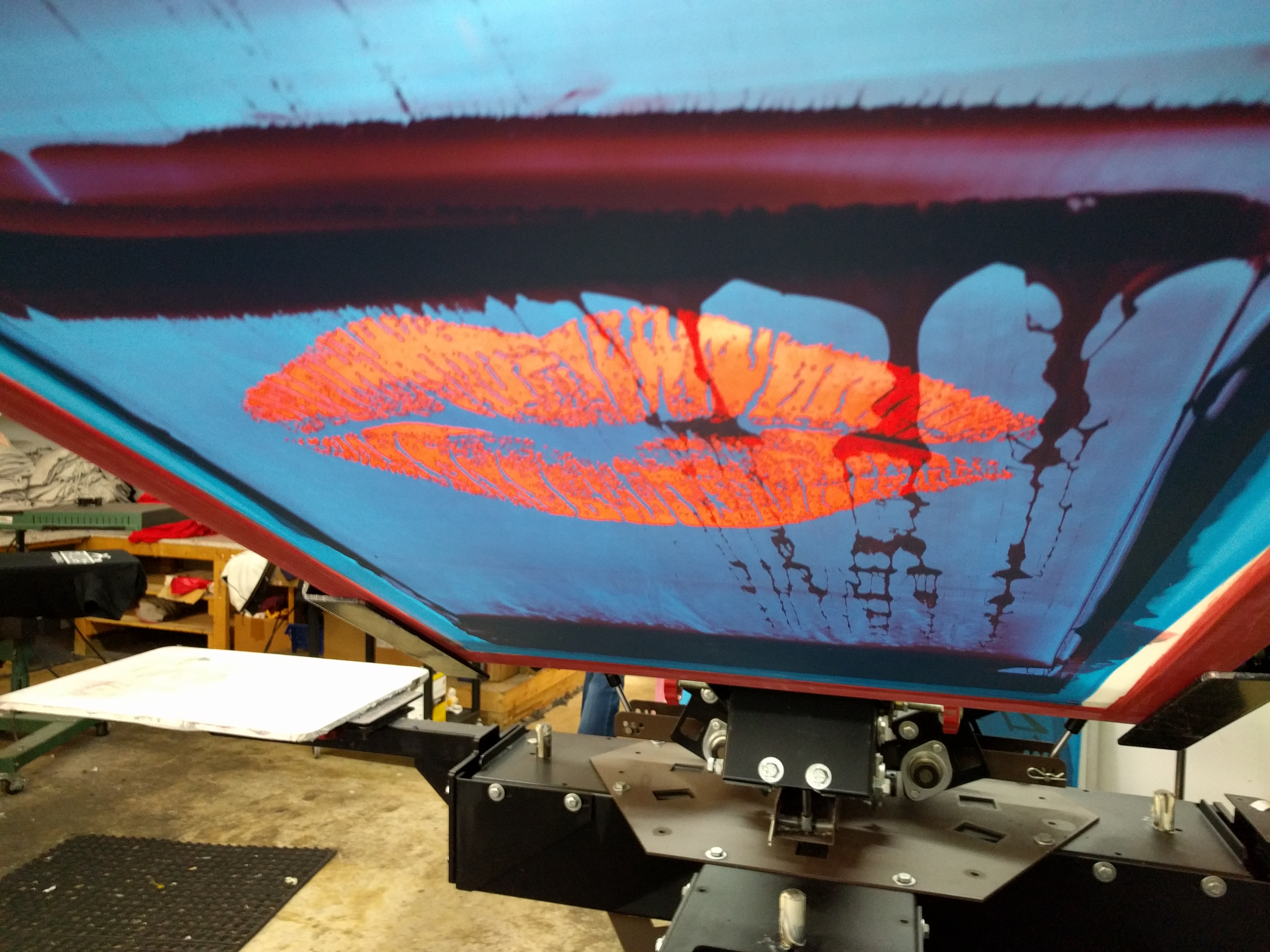

Scarlet ink, mixed with cherry-scented ink from Durascent, is perfect for the lip art Taublieb brought to Blythe's Athletics. "It's a novelty," he explains. "People love novelty."

As soon as the first cherry-scented shirt at Blythe's rolls off the dryer, everyone on staff is hooked, wanting their own version of the fun and funky print. Taublieb helps them decorate the prints with foil and other embellishments as a low-time and low-cost way to add value. "This is the part I enjoy, when everyone gets excited and pumped up," Taublieb admits.

Taublieb helped Blythe's staff print their very first simulated-process color job, a tutorial that boosted the printers' confidence and sparked their enthusiasm. "It's almost like you want to pet it, it looks so real," says Connie Hogge of the realistic ram's head she printed.

Taublieb also showed the production staff at Blythe's Athletics how to create a print using water-based and discharge inks, plus foil accents. "It's a little stinky, but it's a lot of fun," Taublieb says of working with discharge inks.

Stay Ahead of the Curve

Subscribe to ASI's industry-leading newsletters.

All the award-winning content from ASICentral and Print & Promo Marketing, delivered right to your inbox.