Strategy June 12, 2024

Everything You Want To Know About Direct-to-Film, the Hottest Trend in Decoration

The latest advancement in decoration technology is cheaper, faster and better – but not without its downsides.

When solar eclipse mania overshadowed the country this April, apparel decorator Z Shirts was ready. The company – situated in the path of totality in Shelbyville, IN – set up an online store in conjunction with the Shelby County tourism department, offering half a dozen eclipse-themed shirts that featured multicolor designs on the front and back.

“I don’t even know how many colors there were in each of those designs, but it was a lot,” says owner Jennie Livezey. “If we were to try and screen print that, it would have been impossible.”

Z Shirts in Shelbyville, IN, used direct-to-film printing to handle on-demand online orders of solar eclipse shirts produced in conjunction with the Shelby County tourism department.

Instead, Z Shirts turned to direct-to-film (DTF) technology, which allowed the company to easily print full-color, complex digital designs on the garments, whenever an order came into the online store. “Everyone who got those shirts loved them and thought they turned out great,” she adds.

Megan Urban, owner of Idntiteez in Marysville, KS, is also enthusiastic about the transformative power of DTF: “It’s been totally just night and day of how we run our business.”

The technology has helped her small apparel decoration shop grow dramatically in the two years since she purchased a printer – but, perhaps more crucially, it’s brought the small-business owner the ever-elusive concept of work-life balance. “There were a lot of times I was here until midnight every night trying to get stuff done,” she says, adding that the streamlined print-and-press process of creating a DTF transfer and placing it on a garment has allowed her to clock out by dinnertime most evenings.

Walk the floor of any decoration-heavy trade show of the last couple of years, and you’re likely to have been inundated by a flood of booths dedicated to direct-to-film equipment and supplies. The much-hyped digital technology has enjoyed a growth trajectory that echoes the direct-to-garment revolution of the early 2000s – albeit on a fast-forward, truncated timeline. In other words, DTG walked so that DTF could run.

“DTF is a disruptive technology,” says Jay Busselle, a decorating veteran, frequent industry speaker and vice president of marketing at Equipment Zone. “It’s emerging, and it’s exploding.” Busselle explains that 20 years ago, the journey toward becoming proficient with DTG was a “really bumpy ride” that proved difficult to some, but provided valuable lessons to those who stuck with it over the years.

“With DTF,” he adds, “we knew the ride was going to be better and quicker – with a much faster adoption rate – both because of the flexibility of the actual product and because of all the lessons learned from DTG printing.”

When it comes to DTF, decoration experts see a lot of upsides – the equipment is affordable, it’s relatively easy to master, it enables detailed, full-color designs and on-demand production, and prints can be applied to a variety of substrates. But, they warn, it’s not quite the silver bullet solution some would like it to be. As with any nascent technology, there are kinks to work out and improvements that will come over time. And there are still plenty of instances where more traditional decoration methods, like screen printing, have an edge. Let’s explore the upsides, downsides and practical considerations for apparel decorators and promotional products distributors.

Jump to a Section

The Basics

Benefits

Downsides

Safety and Sustainability

Future Advancement

What Is DTF Printing?

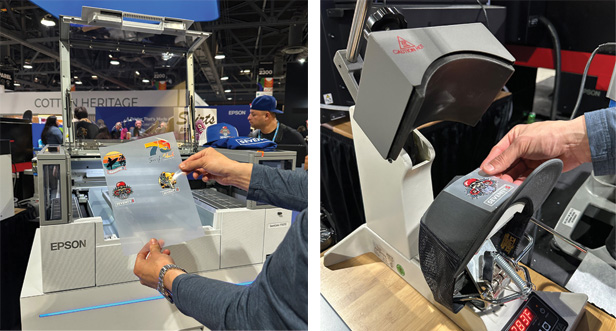

Epson demonstrates some of the capabilities of DTF printing at a recent trade show.

DTF printing is a method of transferring digital designs onto fabrics and other substrates – a “cousin” to more established transfer technology like screen-printed transfers. However, screen-printed transfers typically use plastisol ink and are usually only one- or two-color designs. DTF uses water-based inks in a full range of CMYK colors, plus white; with higher dots per inch (DPI) than a typical transfer, it allows for photorealistic images and fine details, Busselle says.

The technique began catching steam in the early 2020s – with Chinese company Polytech demonstrating a DTF printer back in 2018. In fact, many of the earliest DTF printers came from China, often as modified Epson printers or platforms using Epson printheads, according to Johnny Shell, director of Keypoint Intelligence’s functional and industrial printing consulting service.

Decorators use an inkjet printer to print onto a special transfer film – either onto sheets or a roll – then apply a powder adhesive to the wet ink. Some machines have built-in or auxiliary shaker units to add the powder; in more rudimentary setups, decorators apply powder manually, shaking off the excess into a tray.

The powdered design is then passed under a heat press to cure. “You’re not actually pressing, but hovering,” says Lily Hunter, product manager for professional imaging at Epson America. “It’s almost like creating a drawer.” In fact, some manufacturers offer tabletop dryers with a pull-out drawer for curing DTF transfers, rather than the clamshell styles often used for other transfer applications.

Once the film is cured, the design can be transferred to the substrate, using a heat press to melt the adhesive and bond it to the fabric. After pressing, the film is peeled away – leaving a vibrant, durable print. Originally, films had to be “cold-peeled,” but film and ink manufacturers have also been developing warm- and even hot-peel solutions, allowing decorators to remove the film right after pressing and speed up production flows, Hunter says.

What Are the Benefits of DTF?

There are a variety of reasons behind the rapid adoption of DTF technology in the apparel decorating and promo products industries. Here are a few that proponents tout.

It allows for vibrant, detailed designs: One of the most-cited benefits is the brightness of the color and the ability to print highly detailed designs. “You can get a nice crisp image with a lot of colors,” says Renee Matsushima, owner of Tee Mart Apparel in Chicago, which has found success ordering DTF transfers from vendors and applying them to T-shirts and other items.

It’s a bonus for decorators who care about high-quality design, Busselle adds: “We’re not doing one-color, left-chest logos. We have the whole color palette to play with. We can get back to themes and design quality. We can stop doing logos on stuff, and we can tell stories graphically.”

It’s “substrate agnostic”: Stakes Manufacturing (asi/88974), an Eastlake, OH-based large-scale print-on-demand decorator, was an early adopter of DTF more than three years ago, adding on to its already robust direct-to-garment operation. “We’re running DTF seven days a week, two shifts a day, putting out tens of thousands of units a day,” says owner Jed Seifert. What makes the technology so revolutionary, he adds, is that it’s “substrate agnostic.”

Decorators can print on a variety of fabrics – polyesters, nylons cottons, blends – and even some nontextile surfaces. They can also print on locations that would be harder to reach with screen printing. Stakes Manufacturing has been able to print over seams, onto caps and other headwear, backpacks and on a variety of outerwear that was traditionally left to embroidery – such as rough-textured, heavy-duty Carhartt jackets, puffer coats and fleeces, Seifert says.

“This is really a game-changer because of all the different things you can decorate that you just couldn’t do with DTG,” he adds.

It supports on-demand production: With the rise of e-commerce and concurrent desire to cut back on inventory, print-on-demand business models have thrived. “It’s been very attractive to many people for the last decade for lots of reasons, both from a financial perspective, but also from a planet perspective with reducing apparel waste,” says Josh Ellsworth, chief revenue officer at St. Clair, MI-based Stahls’ (asi/88984), which offers UltraColor MAX DTF transfers to distributors and decorators.

Dye sublimation and DTG have both served the on-demand market, he adds, but those techniques have limitations that make it difficult to scale operations. “Direct-to-film really eliminated all of those limitations and potential friction points, allowing distributors and decorators to just say yes to print-on-demand on a variety of fabrics, with a multitude of logos and colors,” Ellsworth says. “It just checks the boxes on what we’ve always imagined print-on-demand could look like.”

It can streamline production: Compared to screen printing, DTF requires very little prep work, especially since you don’t have to worry about burning screens, setting up presses, tearing them down or cleaning and reclaiming screens – all those extra steps “that kill a screen printer’s productivity,” says Brad Belk, a managing partner for Axiom America, which sells Arcus DTF printers. “With DTF, you just pull up a design, print it, apply it and there it is,” he adds. It’s ideal for smaller or mid-size orders, freeing up a decorator’s screen-printing setup for high-quantity runs with fewer colors.

DTF also has an edge on DTG, in that decorators don’t have to pretreat a substrate before printing. “Pretreating has been a thorn in the side for direct-to-garment printers,” Busselle says. “DTF eliminates that process, which has been a godsend for a lot of people.”

And for distributors and decorators accustomed to doing print/cut with heat transfer vinyl, DTF is an attractive alternative for one major reason: There’s no need to weed out excess vinyl from a design – a tedious, finicky process “that most people absolutely hate,” notes Hunter of Epson.

Plus, DTF allows decorators to do “gang sheets” – putting multiple images onto one sheet of film. A perfect scenario for DTF would be adding a slew of team names and numbers to sports uniforms, says Nate Sprowell, vice president of direct to film at 613 Originals (asi/87218) in Mahwah, NJ. “The beauty of DTF is you can do 100 different names and numbers without messing with all the cutting and weeding of vinyl,” he adds.

There’s a low barrier to entry: Compared to other decorating techniques, the capital expenditure of installing a DTF setup in your shop is relatively inexpensive, says Seifert, noting however that many decorators aren’t considering the cost of consumables – like film and ink – when factoring out cost. High-end DTG equipment could clock in around $500,000 to $1 million, Seifert adds, whereas with DTF you can get a quality piece of equipment on your shop floor for $30,000 to $50,000.

The technology is also relatively simple to learn. It could take as long as two years to master all the intricacies of screen printing, Busselle says, but with DTF, “you’ll be up to speed in 30 to 60 days.”

Another reason that DTF has taken off in popularity is the fact that most DTG printers can be repurposed to handle DTF (and, in fact, many equipment manufacturers are advertising their machines as DTF/DTG hybrids). “It’s like getting two printers in one,” Busselle says. “You can use the same printer, with the same software and same ink; you’re just reversing the order in which you print and mirroring the image for DTF.”

What Are the Potential Downsides of DTF?

Though its many selling points make DTF seem like a no-brainer, decorators warn that the budding technology isn’t perfect, nor is it appropriate for every imprinting scenario. Consider these points before going all-in on DTF.

Skill still matters: Although it typically doesn’t take as long to get up and running with DTF, compared to many traditional decoration methods, there’s a gap between understanding how to use the equipment and mastering it. Seifert likens it to automotive racing: “Anybody can hit the gas and get the car going on the road, but you’re not going to drive it nearly as fast as a professional driver.”

If you plan to add DTF to your operations, it’s important to find a manufacturer that offers robust training, troubleshooting and customer support. Even with all the setup and training provided, says Livezey of Z Shirts: “For us, it was still quite a learning curve because the machines are very particular.”

It has a “plasticky” hand feel: One of the drawbacks of DTF, for many, is the hand feel of prints. “It’s more plastic,” Seifert says. “It feels more like an old-school transfer stuck to the front of your shirt.” He adds that equipment and supply manufacturers have made headway in creating DTF transfers with a softer hand feel, but there’s still a lot of room for improvement.

The hand feel isn’t necessarily a problem for smaller graphics on tees, which allow for breathability, Hunter adds, but DTF might not be the right choice for a large, blocky decoration on apparel.

“If you want a softer hand, and it’s a big, graphic look, use DTG instead – you’ll get a better feel,” Hunter recommends.

It’s not ideal for large print runs: DTF is generally a quicker process than DTG – “Our two-head machine can produce 110 linear feet in an hour in high-quality mode, which is far faster than DTG,” Belk boasts – but it’s not as fast as a screen-printing press that’s fully set up and churning out graphics. For one- or two-color orders in large quantities, screen printing is still probably the better option.

Another wrinkle? “You basically have to babysit the machine the whole time,” Livezey says. “It’s not like on embroidery when you can load them all up, start them and go do something else.”

Your equipment might become obsolete quickly: Though it’s relatively inexpensive to buy DTF equipment, one important note is that “because it’s in its infant stages, the equipment can become outdated faster than anything else,” Seifert says. Decorators who bought screen-printing equipment 10 years ago will likely be able to continue using it for decades to come, he adds, but DTF technology is “progressing at such a rapid clip” that decorators investing in the top equipment right now might have to replace it within a handful of years to keep up.

“People really need to think about their investments long term and see how quickly things are changing,” he adds.

Beware of a backlash: DTF’s stratospheric rise in popularity means everyone wants a piece of the pie – and not everyone in the market is offering high-quality equipment and consumables. “We all thought we would see the technology vastly improve in the last two or three years, with better machines and better inks and better powders, but what we’ve actually seen is a little bit of the opposite happening,” says Jason Ziga, senior vice president and general manager of Transfer Express (asi/91804), a division of Stahls’. “There are so many entrants coming into the market throughout the world, and we’re seeing people trying to cut corners.”

The low barrier to entry means “almost anyone can jump in and become a boutique transfer manufacturer, so there’s always going to be variability in quality,” adds Ellsworth. That shouldn’t necessarily deter decorators from buying DTF equipment or transfers, but they may not want to brand their finished products as having been decorated with direct-to-film, he notes. “There’s certainly going to be a lot of negative perception out there about some DTF transfer quality,” he says.

What About Safety and Sustainability?

One of the benefits of DTF transfers – like this UltraColor MAX design from Stahls’ (asi/88984) – is that it’s “substrate agnostic,” allowing for greater decoration flexibility.

DTF checks a lot of sustainability boxes, since it uses water-based inks, rather than plastisol. Plus, it enables on-demand printing, which cuts down on potential textile waste, since decorators can fulfill orders on an as-needed basis, and end-users aren’t saddled with an excess of inventory they’re unable to sell. Still, one area to consider is that the carrier sheets – the film that graphics are initially printed on – aren’t recyclable after use.

Generally, they’re made from polyethylene terephthalate (PET), and though the substance is often touted as one of the most-recyclable of plastics – think water bottles being remade into new bottles or rPET polyester fabric – DTF carrier sheets have a “special receptive coating” to attract water-based inks. That coating would negatively impact the downline recycling process, unless the recycler has some kind of special technology to remove those chemicals, Ziga says.

Another thing to think about is the adhesive powder that’s applied after the graphic is printed onto the film. “There are powders on the market that I would personally advise people not to use, even though the resulting hand feel is really nice,” Belk says. “The powder is just ground too fine, and it’s going to be a health hazard, especially if you’re trying to apply it by hand. You don’t want to inhale that powder.”

What Does the Future Hold for DTF?

As DTF technology advances, expect manufacturers to introduce machines that achieve quicker output, as well as improvements in ink technology – perhaps allowing for neon colors, dimensional prints and other special effects, experts say. Companies are also likely to develop new methods for applying adhesive powder in a more efficient and streamlined way.

“Every step of the way there are going to be improvements for faster production,” Hunter says.

Also likely to come in the future are more environmentally conscious raw materials that “check some of the boxes on recyclability,” Ellsworth says. European companies, in particular, have been dedicating resources to creating more sustainable films, perhaps made of a hybrid or even a paper material, Busselle adds.

And, of course, there are likely to be plenty of other tweaks and improvements in the coming years that aren’t easily predicted. What’s clear, however, is that DTF isn’t just a passing fad.

“Any of the naysayers on DTF are the same people who were naysayers on DTG back in 2007,” Seifert says. The technology has its limitations, but Seifert notes there’s something important to keep in mind: “We’re in version 1.0 right now.”

3 Ways To Enter the DTF Market

Before you invest in direct-to-film printing, it’s important to evaluate your overall business needs and capacity. In some instances, investing in DTF equipment so you can control the quality and output makes the most sense. In other cases, outsourcing the creation of the transfers and even fulfillment of orders is a more viable option.

Option 1: Do Everything in House

Setting up an in-house DTF operation isn’t too difficult; you’ll need a printer, a heat press and someone to operate both. But the devil is in the details. DTF equipment won’t thrive in a dusty, dirty, hot environment, says Jay Busselle of Equipment Zone. So, installing your printer in the same place where you do screen printing, for example, would likely be a bad idea. It’s also crucial to do a realistic calculation of how much the equipment is costing you – including labor and consumables, not just the initial capital outlay – and weigh that against how much business you expect the machine to bring you.

Option 2: Outsource the Transfers

In this scenario, a distributor or decorator only needs a heat press to get started and would contract out the creation of a DTF transfers to another decorator. It’s a good idea to vet your contractor first to ensure quality and consistency of product, plus speed of delivery. Request multiple samples and do some test applications to ensure the colors are true to your clients’ needs and that the adhesive was applied evenly. Josh Ellsworth of Stahls’ says to be wary of out-of-registration transfers with a hairline of white or a fuzziness around the edges, which could be the result of low-quality equipment or an indication that they were printed at a draft quality, sacrificing quality for speed.

Option 3: Outsource Transfers and Fulfillment

This method offers the least control, so it’s imperative to form strong partnerships with vendors you can trust to deliver on speed and product quality. Generally, this method works best for distributors with robust e-commerce platforms and automation solutions. Outsourcing printing and fulfillment allows you to focus solely on marketing and sales – not worrying about big equipment purchases or maintenance.