Commentary January 28, 2026

How To Sublimate the Top of a Bucket Hat

Angie Meese of That Shirt Shack explains how she engineered a special ABS plastic prototype to enable sublimation on the tops of bucket hats for the Branding Together podcast merch project.

Key Takeaways

• Angie Meese of That Shirt Shack in New Philadelphia, OH, developed a custom heat-press platform with i-Group Technologies to enable dye sublimation on the top of recycled polyester bucket hats.

• Meese used a hat press for the sides of bucket hats and for trucker caps, pressing at 400 degrees for 60 seconds and adding sublimated patches and embellishments.

• Her goal, when decorating for the Branding Together podcast merch project, was to create a variety of unique designs that looked cool but weren’t overly expensive.

For the Branding Together merch project, I was tasked with using dye sublimation to decorate bucket hats and trucker caps from Atlantis Headwear (asi/37380), both of which were made from recycled polyester. The bucket hats, in particular, proved challenging because I don’t know of anything on the market that will let you sublimate the top of a bucket hat.

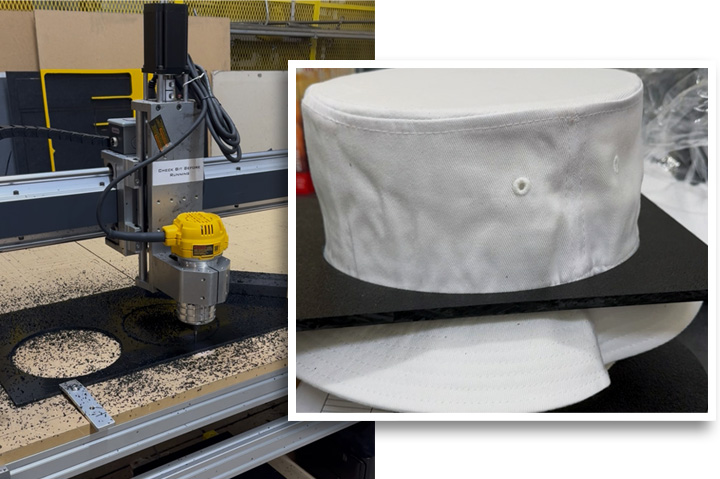

Working with the team at i-Group Technologies, we created a platform to ensure there would be enough pressure for the top of the hat. The design had to be something stable, even with a little bit of shifting because we’re not pressing it on a metal plate. We created a prototype using ABS plastic with a heat-resistant barrier, cutting it on the Probotix GX5050 CNC machine. Once completed, I placed the prototype on the track of a Stahls’ (asi/88984) Fusion IQ heat press, with the platen fully extended.

Angie Meese and the team at i-Group Technologies fashioned a prototype out of ABS plastic to enable heat pressing on the top of a bucket hat. (photos courtesy of Angie Meese)

I wasn’t scared of decorating the sides of the bucket hat, since I have a hat press. Using the Stahls’ Hotronix 360 IQ hat press, I was able to decorate the sides, breaking it up into smaller sections and pressing them little by little. I also used the hat press to sublimate on the trucker hats.

Each hat was pressed at 400 degrees Fahrenheit for 60 seconds.

Other decorations used on the trucker caps included a 100% polyester patch that I dye sublimated before attaching and select hat embellishments purchased on Amazon to complete the designs.

What I wanted to show with this project is that you can make something that’s really cool without breaking the bank in the process. In total, the whole project wasn’t expensive at all, but we were able to create so many different Branding Together looks for the hats.

For this year’s fashion shoot in the winter issue of Counselor magazine, we asked decorators to create a cohesive mini-collection of branded merch, using garments and accessories supplied by Stanley/Stella (asi/89011) and Atlantis Headwear (asi/37380). Decorators also documented their design and production process in tutorials and reflected on the process in short video interviews. Check out all the stories on ASI Central and Apparelist:

- Branding Together January episode

- Branding Together January mini-episode

- Build a Brand

- DTG Tutorial From Deana Iribe of The Print Bakery and DTG Connection

- Embroidery Design Tips From Jeremy Picker of AMB3R Creative (asi/590243)

- Screen-Printing Tutorial From Lon Winters of Graphic Elephants

- DTF Tutorial From BeeGraphix

- Heat-Transfer Tutorial From TopShelf Printers