Strategy June 25, 2018

Will 3-D Printing Upend Promo Supply Chain?

A Brooklyn company is using 3-D printing to mass produce promotional products. Find out what this means for our industry.

Like the items it seemingly creates out of thin air, the possibilities for 3-D printing appear limitless. Manufacturers have already been creating medical devices and car parts. 3-D printed food is a legitimate thing. One company printed and erected a full-size house in just 24 hours.

Some futurists even predict that one day, consumers will simply 3-D print the products they need and completely circumvent the retail supply chain.

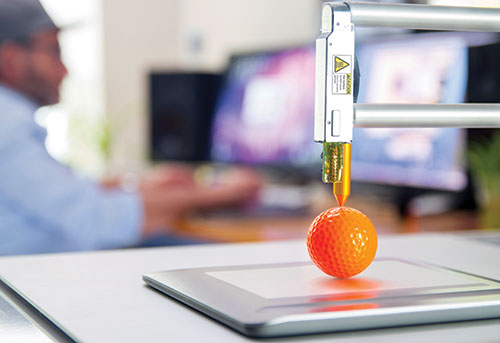

That last part certainly hasn’t happened – consumer adoption of in-home 3-D printers has slowed after initial early hype. Industrial manufacturers, on the other hand, are as bullish as ever. As recently as 2015, over 70% of U.S. manufacturers were applying 3-D printing technology in some way, according to PricewaterhouseCoopers. While most use it for prototyping and experimentation, the idea of production powered by 3-D printing is beginning to take hold. That leap could revolutionize hundreds of industries – including promotional products. In theory, 3-D printing offers the ability to create customized products, built to spec domestically in low runs and at affordable costs. But so far, that notion has stayed more dream than reality, limited by 3-D printing’s inability to scale up production in an efficient and cost-effective manner.

Until now, says one company.

A Whole New Dimension

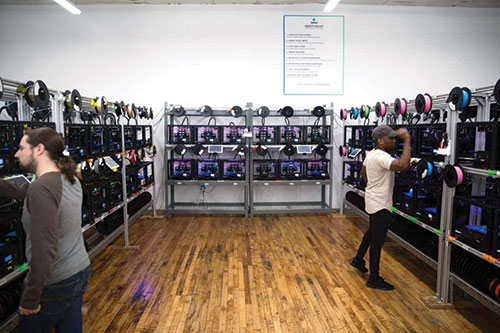

Nestled in a graffiti strewn “digital factory” in Brooklyn, Voodoo Manufacturing is striving to bring 3-D mass production to life. The two-year-old company has the capability of producing high-volume 3-D printed products – up to 10,000 units so far – at prices competitive with injection molding. Voodoo operates more than 200 3-D printers to make thousands of plastic parts and products in short periods of time.

“3-D printing has been around since the 1980s, but it was used only for high-end components like aerospace and medical devices,” says Jonathan Schwartz, co-founder and chief product officer of Voodoo. “It had never been a possible method for producing products consumers would buy and interact with or were being made at any sort of high volume. Our goal was to change that.”

Among the unique custom promos Voodoo Manufacturing has created with 3-D printing includes a figurine for the mobile game War Dragons, gyro spinner self-promo and Superman-themed razor.

Among the unique custom promos Voodoo Manufacturing has created with 3-D printing includes a figurine for the mobile game War Dragons, gyro spinner self-promo and Superman-themed razor.

Since they were students at Harvey Mudd College in Claremont, CA, Schwartz and fellow co-founders Max Friefeld and Oliver Ortlieb were intrigued by 3-D printing and how the newly accessible technology could change manufacturing. At school, the engineering and computer science majors first developed software that enabled e-commerce between 3-D printing firms and end-users.

They were bought out by MakerBot Industries LLC in 2014, and a year later joined up with Patrick Deem (at the time MakerBot’s head of M&A) to start Voodoo. The company’s first project, even before it had moved into its offices, was creating promotional keychains for Viacom brands Nickelodeon and MTV. That took the company in an unexpected direction.

“When we started, we didn’t predict we’d find a strong fit in the promotional products market,” Schwartz says. “But people in that industry are looking to make something highly unique, meaningful and specific to an event or customer. We took it a step further by making entirely unique products that were never made before, and we make them without any minimum order quantity.”

On the surface, Voodoo’s proposition looks like a compelling alternative to traditional manufacturing. Most manufacturing methods have high startup costs because injection molding can cost thousands of dollars or more. To buy a mold for just a few hundred units often doesn’t make economic sense.

Alternatively, because 3-D printing is digital technology, there’s little to no setup cost. The only thing Voodoo needs to start is a digital file of the concept. “We act as both supplier and distributor depending on the customer,” Schwartz says. “We work with marketing professionals who have never manufactured anything, but they know what they want. Our design team and factory will take any idea all the way to finished product.”

Voodoo has already infiltrated the promotional products industry, including working with Top 40 distributors Boundless (asi/143717) and PromoShop (asi/300446). Memo Kahan, president of PromoShop, says the company turned to Voodoo when a client wanted a bar promotion for people to sample new alcohol. The client wanted 18 plastic alligators that could hold shot glasses, needing six in three different sizes.

“Voodoo worked with us to find a solution that was cost effective in every sense,” Kahan says. “They were ingenious – their machine could only produce big sizes, so they cut it into different pieces that could be attached together for one big alligator. Our client was really happy.”

PromoShop has worked with Voodoo for other orders, including a project where the technology was able to replicate people’s faces from images off an iPhone. “It’s one of those things that scare me because it’s really powerful,” Kahan says. “But it’s also exciting because we can be a lot more creative, resourceful and not have to wait for things from overseas, especially in pre-production. Sometimes molds take months and months, and by the time they arrive, the client doesn’t want that piece anymore.”

Future Uses

While still a relatively new technology for the promotional products industry, 3-D has found a place. Top 40 supplier Ariel Premium Supply (asi/36730) doesn’t use the technology for production of its stress reliever line, but does rely on it for product development purposes. Before implementing 3-D printing a few years ago, Ariel’s product development process was costly and time-consuming, a wait-and-see process of sending an idea to an overseas factory and then hoping the piece sent back matched what was originally envisioned.

“3-D printing and 3-D rendering has made us faster and far more accurate,” says Christopher Duffy, director of marketing at Ariel. “It lets us know on the Asian end we’ll get the same exact thing we sent over.” The new process at the company begins with brainstorming new shapes of stress relievers and then making a 3-D rendering of the dimensions. The rendering is then printed, and a hard plastic 3-D model is passed around the company offices so the staff can see how it fits in their hands. Once everybody approves, the digital file is sent to the factory overseas, which manufactures the final product.

The more than 200 3-D printers at Voodoo Manufacturing in Brooklyn can produce up to 10,000 units of a custom product.

The more than 200 3-D printers at Voodoo Manufacturing in Brooklyn can produce up to 10,000 units of a custom product.

“It’s a competitive advantage for us because we’re doing our own designs,” Duffy says. “We just keep buying newer 3-D printers because the technology is always changing. Even though end-buyers look at stress relievers as a commodity, we build in a lot into the back end. What goes in before the client even sees it is the fun part.”

As beneficial as 3-D printing has been on the back end, the technology is still practically invisible to end-buyers. “We haven’t had the demand for it,” says Jamie McCabe, president of McCabe Promotional Advertising (asi/264901). The London, ON-based company has a 3-D printer in its office it has occasionally toyed with. “Maybe we should be more proactive in asking our prospects, but we haven’t had a single request for it,” McCabe adds.

As the technology becomes proficient, consumer demand is likely to grow, especially as major brands such as General Electric, Hasbro and Nike invest and work toward mass-manufacturing capabilities. “We’ve seen a couple innovations leading toward greater automation and greater ability to print more multiple parts,” says Matt Stultz, digital fabrication editor at Make Magazine, a publication covering the DIY 3-D printing community. “3-D printing will create a greater diversity of objects for mass manufacturing. It may be a slower process than injection molding, but it will offer more opportunities for customization.”

Perhaps at some point in the future, as the technology is continually refined, those powers will be placed directly in the hands of consumers and creators. In the meantime, Voodoo and similar companies are presenting themselves as the key to unlocking 3-D production. Earlier this year, the company launched Fulfilled by Voodoo, a manufacturing and fulfillment service for entrepreneurs wanting to start an online business selling 3-D printed products. Users can outsource the manufacturing, quality control, assembly, packaging and shipping for their products to the company’s robotic 3-D printing factory through the service’s shop front integrations with popular online marketplaces such as Amazon and Etsy.

As proof of its fulfillment service, the company launched its first homegrown brand in March: Zooheads, which sells a variety of exotic, eco-friendly, 3-D printed animal shower heads. “We want to dive deeper and create new relationships with as many customers as we can,” Schwartz says. “We will continue to build our services so it’s as easy as possible to work with us, where people can come to us even if they don’t have a fully baked idea, and we’re able to work with them to create one.”

John Corrigan is a staff writer for Advantages. Tweet: @Notready4Radio. Contact: jcorrigan@asicentral.com