Research September 03, 2025

Why Labels Could Be the Next Big Opportunity in Promo

Digital printing technology makes custom labels faster, more flexible and more profitable.

Key Takeaways

• Labels provide a practical entry point for print providers moving into packaging, offering lower complexity than other formats and broad applications across food, beverage, personal care and promotional products.

• Digital printing has made label production more accessible, allowing for cost-effective short runs, faster turnaround times and flexibility in design.

• In-house production helps promo firms save time and money while improving efficiency; investments in digital presses and finishing systems can further streamline workflows and expand customization options.

• Embellishment and personalization – including foil, embossing and custom variable labels – give promotional products companies opportunities to differentiate their offerings and enhance brand impact.

As print providers pivot toward packaging, the label segment offers an ideal starting point. While all packaging segments provide stability and growth potential, labels offer a less complex structural application, reducing the barrier to entry. There are nuances to label printing and production, however, that must be understood before incorporating it into a print business.

Cory Francer is an analyst at NAPCO Research, part of the PRINTING United Alliance – ASI’s strategic partner.

For promotional product companies, the availability of digital printing and the potential to enhance promo items with custom labels has made this segment more enticing than ever. And given the prevalence of labels across the promo segment, bringing label production in-house can lead to time and cost savings, additional revenue and increased customer satisfaction. But to be successful in the label realm, promotional product companies should have a strong grasp of:

- The equipment needed to produce labels

- How to maximize production efficiency

- Key trends in label enhancement and embellishment

Label Printing Basics: What To Know Before Getting Started

Printed labels appear on several different types of products and packages and can be printed using a variety of materials. There are also numerous styles of labels, ranging in complexity and sophistication. For those getting started, it’s best to focus on the two primary label formats – pressure-sensitive and cut-and-stack or glue-applied labels. Pressure-sensitive labels are often described as a high-end sticker, as they feature a full adhesive backing and are applied to a surface using pressure. Cut-and-stack or glue-applied labels, meanwhile, are printed and cut without adhesive, which is then added during the application process.

Dedicated label printing businesses primarily use roll-fed flexographic printing presses. These are conventional printing machines that implement flexible plates mounted on cylinders and are often used for high-volume label runs with static graphics and text. Though flexography is the most prominent label printing technology, the proliferation of digital printing platforms has made label printing more accessible than ever, with equipment ranging from entry-level to advanced high-production platforms. Digital printing removes the plates and tooling from the production equation, resulting in increased ease of use and cost-effective short-run jobs.

Another aspect of labels that makes them an ideal entry point into packaging is their abundance across nearly every market segment. This includes consumer packaged goods (CPG) segments such as food, beverage and personal care, as well as pharmaceutical and industrial labels. For the promotional products industry, labels may already be a key component of products they produce, and bringing printing in-house can lead to time and money savings.

For example, Counselor Top 40 supplier SnugZ USA (asi/88060), based in West Jordan, UT, has digitally printed labels in-house since 2007 and has since upgraded to two Epson SurePress L-4033AW inkjet label presses. SnugZ offers a variety of products including health and beauty items, drinkware, corporate gifts and personal care products. And given the flexibility that digital label printing provides, the company can nimbly accommodate a wide variety of label shapes, sizes and versions.

“[We have] the ability to produce high quantities quickly and efficiently with a quality imprint,” Justin Gukeisen, chief operating officer, said in a 2023 interview with NAPCO Research. “It also provides us with the ability to modify size, shape and give the customer the flexibility of offering a fully customizable, full-color label to decorate their item.”

Maximizing Efficiency With In-House Production

For promotional products companies, efficiency is imperative, as distributors’ clients often have strict deadlines. With any manufacturing process, outsourcing can result in extended lead time, so suppliers taking control of label printing and production can be advantageous.

Raining Rose (asi/80489), a developer and producer of personal care and promotional products spanning lip balm, sunscreen, lotion, skincare, men’s grooming products, deodorant and hand sanitizer, has made labeling these items an important part of its business. The company had previously outsourced its label production, but it invested in its own printing equipment in 2013 and has since installed an HP Indigo WS6900 digital press in its Cedar Rapids, IA, facility.

“Before we started printing in-house, the typical lead time to get labels was four to five days,” Raining Rose Chief Operating Officer Kyle Hach said in an interview with NAPCO Research. “For some products, we can now get a label printed, cut and ready for our labeling equipment in less than 12 hours. We are always trying to find ways to cut our lead times. Cutting three to four days off our lead time by printing in-house versus outsourcing was a major factor in our decision to buy a printer.”

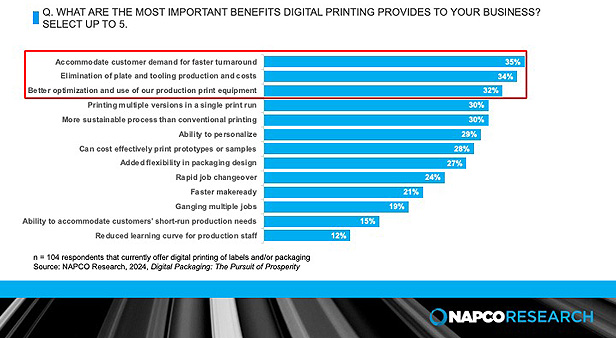

The efficiency benefits of digital printing are also echoed by the package printing industry at large. In NAPCO Research’s 2024 report, Digital Packaging: The Pursuit of Prosperity, more than 100 package printers were surveyed on several digital printing topics. When asked to select the top benefits digital printing has provided to their businesses, multiple efficiency advantages rose to the top. This included accommodating customer demand for faster turnaround, elimination of plate and tooling production and costs, and improved overall equipment optimization.

Hed for powerpoint slide: Efficiency Advantages of Digital Package Printing

Advancing Capabilities: Finishing, Embellishment & Personalization

Bringing label production in-house can lead to increased efficiency and reduced costs, but printing is just one part of the equation. Finishing processes, embellishment and personalized or customized components of the label can take a simple design to new heights.

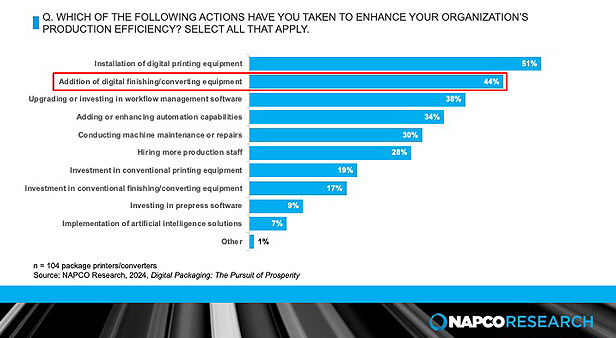

For those bringing digital printing of labels on board, investing in a digital finishing system that can accommodate short-run work can help maintain end-to-end production efficiency. Digital die cutting platforms, including laser cutting systems, are readily available, and many can be installed either in-line or nearline with a digital label printer. While many labels are produced in a standard shape, it’s not uncommon for customers to demand custom or variable shapes. Having equipment that can accommodate these variables can add value and ensure customers’ visions are fulfilled. Package printers participating in NAPCO Research’s 2024 report indicate that adding digital finishing equipment has also been beneficial to their company’s production efficiency, with 44% having added the equipment for that reason.

Pairing Digital Finishing With Digital Printing

Thinking Beyond Print

Embellishment is another important process in label production and can be a key differentiator. Foil and metallic components, as well as specialty coatings, are common methods of embellishing labels to catch consumers’ eyes. However, tactile elements including embossing and debossing can enhance a label even further through engaging multiple senses. For printers entering the label segment, exploring equipment that has these features built in, or investing in standalone embellishment systems, can be worthwhile.

Another advantage of digital printing equipment is its ability to personalize or customize output. This can significantly benefit promotional products companies, as unlike traditional CPG brands sold in brick-and-mortar settings, the recipient of a promotional product may be known in advance. Because promotional products are often giveaways at events, label printers can leverage the attendee list to digitally print customized labels for water bottles, sunscreen, hand sanitizer or whatever the promo may be.

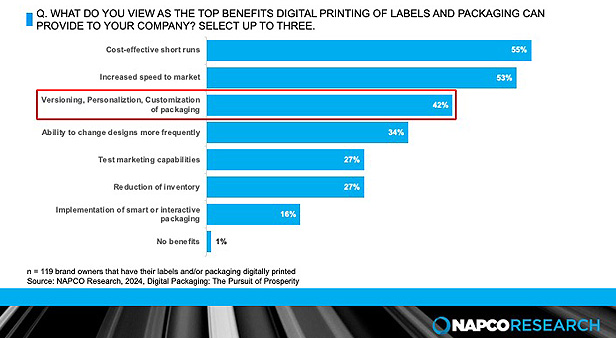

Brand owners who currently buy digitally printed packaging also report versioning, personalization and customization as top benefits of the technology. In fact, when asked to share their top three benefits of digital printing, 42% of brand owners surveyed by NAPCO Research selected these attributes, underscoring the advantages of using packaging to create a personalized experience.

Packaging Personalization Ranked Top Benefit of Digital Printing

Conclusions & Recommendations

Making a move into packaging is becoming increasingly common in the promo industry. For those seeking an entry into this high-growth segment of print, labels can be a great application to start. Widely available digital printing solutions ensure that promotional product companies can access an entry-level option and scale up their equipment as their label printing business grows. Additionally, because labels are two-dimensional, the finishing and converting processes can be less complex compared to other packaging formats.

Despite the lower entry barriers to label printing, however, promo firms seeking to enter this segment must ensure they understand and are prepared for the printing, finishing and embellishment processes in demand across label production. Digital die cutting, for example, can help label printers maintain the efficiency and customization attributes gained in digital printing. Further, being able to offer visual and tactile embellishments such as foil and embossing can enhance how the label resonates with the consumer and make the promo product more attractive.

Finding ways to creatively personalize labels can also be advantageous for promo firms. Particularly when serving an event with a documented attendee list, producing personalized labels to adhere to giveaways can be a great way to forge a relationship with the recipient and promote a positive perception of the host organization.

When adding any new service, education and investment are necessary. But for suppliers seeking to expand capabilities, label printing can be an ideal way to enter the world of packaging.