Strategy February 14, 2025

How To Print Custom Stadium Seats & Rally Towels Using Heat Transfers

This tutorial walks distributors and decorators through the process of adding logos and other graphics to popular game-day promos.

Did you know you can use a heat press to customize items like stadium seats and rally towels? These items may seem unconventional, but they’re perfect for showing off team spirit and making game day unforgettable.

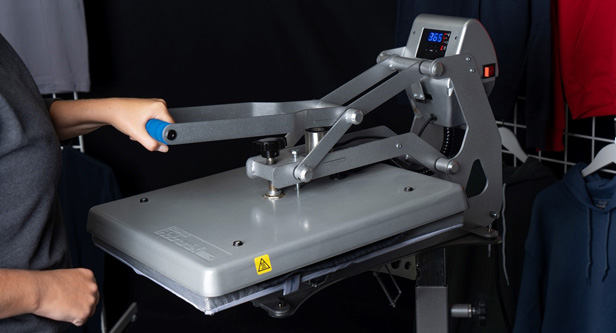

Heat transfers on spirit items are an accessible decoration method for distributors looking to expand in-house services. (photo courtesy of Stahls’)

For promotional products distributors, customizing these sports-related items is a practical way to expand services. To top it off, it’s also an affordable way to bring some decorating services in-house. With the right heat transfers and some simple techniques, you can create professional-looking designs that are durable and eye-catching.

This article guides you through the process of using heat transfers to print on stadium seats and rally towels, step-by-step. Whether adding logos, slogans or team mascots, you’ll learn how to make these items both functional and fun.

Choose Your Transfer

When it comes to customizing rally towels and stadium seats, choosing the right type of transfer is key to achieving vibrant, durable designs that withstand wear and tear. Each type of transfer has unique qualities suited to different needs. Here’s a closer look at how they work for these items:

Heat Transfer Vinyl (HTV): HTV is a go-to option for creating bold one-color designs or simple graphics. It’s ideal for small runs or personalization, as you can cut and weed designs to match team logos, numbers or slogans. HTV works best on smooth, flat surfaces, making tightly woven rally towels and vinyl or coated stadium seats a great match. The application is straightforward, requiring just a heat press and proper alignment.

Direct-to-Film (DTF) Transfers: DTF transfers are ideal for intricate full-color designs that include gradients, fine details or photographs. DTF transfers adhere well to both towels and stadium seat covers, offering high durability. They’re particularly effective on polyester fabrics or coated surfaces, and their ability to stretch without cracking makes them versatile. Plus, DTF transfers work well for medium to large production runs, providing efficiency without sacrificing quality.

Screen-Printed Transfers: Screen-printed transfers are an excellent choice for high-volume projects or when you need a vintage soft-touch finish for one- or two-color logos, which is typical in the team sports world. Screen-printed transfers deliver sharp, vibrant results on cotton towels and offer durability even after multiple washes. For stadium seats, screen-printed transfers can be customized for smooth vinyl surfaces, providing excellent adhesion and long-lasting performance. They’re also more economical for bulk orders, making them ideal for giveaways or large promotional events.

The best transfer type depends on your project’s requirements. For rally towels with smooth weaves, we recommend HTV and screen-printed transfers, while DTF transfers are a better choice if you have full-color, more complex artwork. Stadium seats, often made of synthetic materials like vinyl, pair well with DTF or screen-printed transfers for vibrant, durable designs that hold up in outdoor settings.

How To Decorate a Rally Towel With a Screen-Printed Transfer

Rally towel featuring a screen-printed transfer from Transfer Express (asi/91804) (photo courtesy of Stahls’)

Most rally towels are made from cotton or cotton-polyester blends, offering a soft yet durable surface ideal for customization. When it comes to heat printing, towels with a smoother weave or tighter knit work best, as they provide a flat surface for the transfer to adhere evenly. Avoid towels with heavy textures or deep loops, as these can interfere with the clarity of your design.

Items needed:

• Rally towel

• Screen-printed transfer – for this tutorial, we used Goof Proof from Stahls’ Transfer Express (asi/91804)

• Heat press

1. Set heat press at 365 degrees F.

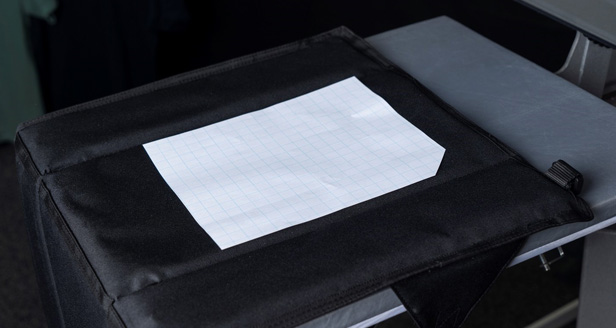

2. Lay towel flat on the press.

3. Pre-press to remove moisture and wrinkles.

4. Position the screen-printed transfer ink side down on the towel.

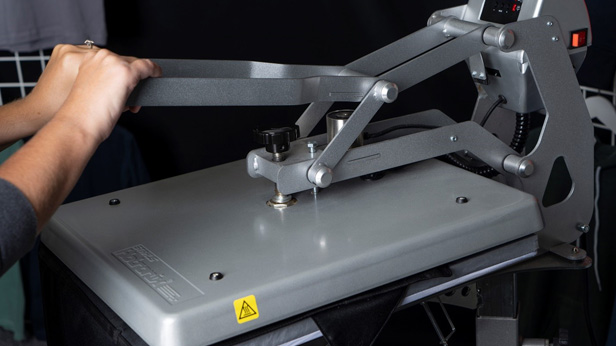

5. Press four to six seconds and peel hot.

How To Print a Stadium Seat

Stadium seat with a two-color heat transfer from Transfer Express (asi/91804) (photo courtesy of Stahls’)

Custom stadium seats may seem tricky to print, but this stadium seat is easy to heat press with just one quick trick: Remove the stabilizer foam and insert a mouse pad. This gives you a firm, flat surface to press and won’t melt the stabilizer.

Items needed:

• Stadium seat

• Heat transfer (we use Goof Proof for this tutorial)

• Mouse pad to avoid seams and obstructions while pressing

• Heat press

1. Remove the stabilizer from inside the stadium seat in the area you will press. It’s held into position by a hook-and-loop fastener, so it’s usually easy to open and remove.

2. Insert mouse pad.

3. Lay the stadium seat on your heat press.

4. Position your transfer ink side down.

5. Press for four to six seconds.

6. Peel hot, and enjoy your custom stadium seat.

Heat printing rally towels and stadium seats with a heat press is a smart way to expand your offerings and bring a brand to life. Whether you’re creating one-off designs or producing in bulk, heat transfers like HTV, DTF and screen-printed options make it easy to deliver high-quality results on a wide range of materials.

The flexibility of heat printing also aligns perfectly with print-on-demand services, allowing you to create only what’s needed, when it’s needed – minimizing waste and maximizing efficiency.

Sue Wilcosky is the director of marketing fulfillment at Stahls’ (asi/88984). She has been with Transfer Express (asi/91804) and Stahls’ for 38 years, serving in both customer service and marketing roles. She has a degree in sport management with minors in marketing and journalism from Bowling Green State University. This tutorial was adapted from the ultimate apparel decorating guide, which first appeared in Apparelist, part of PRINTING United Alliance, ASI’s strategic partner.

Sue Wilcosky is the director of marketing fulfillment at Stahls’ (asi/88984). She has been with Transfer Express (asi/91804) and Stahls’ for 38 years, serving in both customer service and marketing roles. She has a degree in sport management with minors in marketing and journalism from Bowling Green State University. This tutorial was adapted from the ultimate apparel decorating guide, which first appeared in Apparelist, part of PRINTING United Alliance, ASI’s strategic partner.