Close your eyes and imagine the lifecycle of a typical promo product: It’s probably made in an overseas factory – sourced from virgin materials – before coming stateside to be customized and shipped out to a client who then passes it along to an end-user. The grateful recipient uses and appreciates said product, perhaps for several years. Maybe they give it away to a friend or family member when they’re done with it. Maybe they donate it to charity or drop it in a recycling bin. But more than likely the product will one day end up in the trash. It will go into the landfill, where it could remain for hundreds of years without biodegrading. End of story.

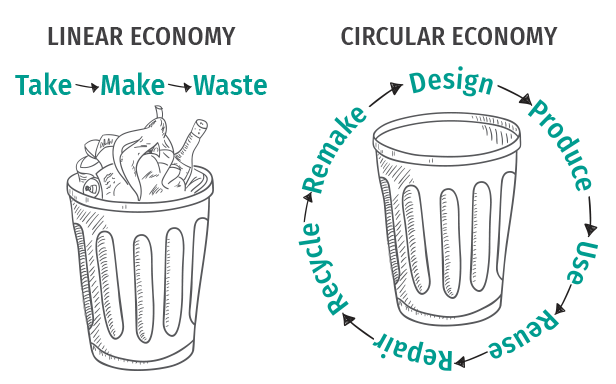

This conventional take-make-waste paradigm is sometimes referred to as the linear economy. And it’s what leads to some chilling statistics: In 2021, for example, only about 5% of 51 million tons of U.S. plastic waste was recycled, according to Greenpeace. Nearly half (47%) of the world’s forests are at risk of deforestation or degradation by 2030, with the world losing forests at a rate equivalent to 27 soccer fields per minute, according to the World Wildlife Fund. A report by the Environmental Integrity Project (EIP), a nonpartisan nonprofit created by former U.S. Environmental Protection Agency (EPA) attorneys, found that half the country’s rivers and streams and one-third of its lakes are too polluted for swimming, fishing and drinking.

But it doesn’t have to be this way.

In recent years, a different concept has gained traction as a sustainable alternative to business as usual: the circular economy. “It’s a cradle-to-cradle approach, a closed loop,” says Lea Coté, a LEED green associate and marketing coordinator for seed paper supplier Botanical PaperWorks (asi/41273). “It’s reusing materials at the end of a product’s life, so they don’t end up in a landfill.”

With a circular model, old or obsolete items and factory-floor waste become the material input to create new products, so that nothing goes to a landfill and natural resources are no longer depleted. Remember the old Lamb Chop earworm, “The Song That Doesn’t End”? Think of this as the swag that doesn’t end.

The Ellen MacArthur Foundation – a U.K.-based charity that works to accelerate the transition to a circular economy – breaks the concept down into three parts:

1. Eliminating waste and pollution

2. Circulating products and material at their highest value

3. Regenerating nature

It will require massive systemic change to truly become circular at an industry level, but there’s evidence that the needle is moving, as individual suppliers and distributors launch programs and shift their mindsets to help clients reach their own sustainability goals. “I think it’s just aligning people’s values, and if you can influence change and put in their hands something that’s more sustainable, it helps them meet their targets,” says Christine Jennings, group quality and compliance manager for Brand Addition (asi/202515), a worldwide distributorship with offices in the U.S., Europe and China. “Sustainability isn’t a one-man race. It’s a big iceberg, and we’ve all got to just chip a little bit off.”

Here’s a look at how promo companies have begun tackling the three tenets of circularity and what you can do to join in those efforts with your own business.

Back in 2012, Doug Jackson remembers getting his hands on his first swatch of recycled performance fabric in the days when only big brands like Patagonia – who could afford to buy hundreds of thousands of jackets’ worth of textile at a time – were sourcing it. The president of Storm Creek (asi/89879) was able to swoop in and buy up some recycled material after a large supplier canceled an order. “I thought it was the coolest thing in the world,” Jackson recalls. “And I wanted to start learning more about it.”

“It’s not just buying fabrics. It’s about making all of your supply chain sustainable.” Doug Jackson, Storm Creek

It wasn’t until about five years later that he was able to routinely source recycled fabric from the mills he worked with and Storm Creek was able to transition in earnest to eco-focused clothing. And it took until around 2020 before the sustainable stories told by Storm Creek’s apparel started clicking with distributors, Jackson says.

Making jackets out of recycled materials was a good start toward eliminating waste and pollution and building a circular system, but it was only a first step in the journey, according to Jackson. Read on for more tips you can implement at your company.

Evaluate Your Supply Chain

“It’s not just buying fabrics,” Jackson says. “It’s about making all of your supply chain sustainable.” That means looking at dyeing mills, fabric mills and even factory partners and making sure they align with your principles. “We probably fired four operations we worked with because they couldn’t handle water the way we wanted. They couldn’t get the certifications we wanted, or they used chemicals that weren’t good for the environment,” Jackson adds.

Storm Creek is also careful to have documentation and certification for every aspect of its garments, so distributors can pass that information along to clients. “There’s transparency that needs to happen,” Jackson notes.

Suppliers and distributors who aren’t paying attention to such details could be in for a rude awakening. “If you don’t understand your supply chain and how it’s being made and who’s involved, not only will you have a lot of environmental and social justice issues, but you have skeletons that could potentially come out and attack your brand and degrade its brand equity,” says Andy Keller, CEO of ChicoBag (asi/44811) and a member of the Promo for the Planet advisory board.

The added wrinkle when designing a circular supply chain is the need to design with an item’s end in mind, right from the beginning. “You’re not just having one-way conversations with partners,” says Irys Kornbluth, co-founder of Everywhere Apparel (asi/53059), which uses a closed-loop model to create apparel basics. “It’s usually a multi-faceted conversation where you’re working with them like a normal supplier, but also asking additional questions, like having access to their waste streams and other questions they’re not used to being asked.”

Build Strong Partnerships

Asking questions and making connections is key. Stacy Savage, owner of consultant firm Zero Waste Strategies, notes that businesses can make requests to their vendors “further upstream” to help cut back on waste that’s being brought into a facility. You can ask for items to be wrapped in recyclable materials, for example, or to be shipped in a reusable, collapsible metal container, she says. “You can have those things written into the contract,” Savage says. “They’ll do it if they want that contract.”

Circular suppliers also forge relationships with other businesses to help divert items from landfills. Refresh Glass (asi/81255), for example, has partnered with local restaurants to collect their empty bottles, keeping them from entering the waste stream. The bottles are then transformed into high-end drinkware and other glass items. Botanical PaperWorks works with other businesses and recyclers to source post-consumer and post-industrial material to create its seed paper. “No virgin materials are being used in production, which is huge,” Coté says. “Then, after the product is made and received by the buyer, the item is planted, and it grows flowers, so it fully breaks down. There’s zero waste and no impact on the environment.”

Create Take-Back Programs

One of the most important aspects of circularity is educating end-users on how to properly dispose of a product when they’re done with it. That’s why take-back programs are so crucial. Everywhere Apparel includes a QR code on each of its garments. End-users can scan it to request a pre-addressed, postage-paid recycling envelope. Marine Layer (asi/68730) offers a similar service through its Re-Spun program which launched in 2019. Any tee can be returned to mailboxes in one of the company’s retail stores or shipped in a prepaid mailer to receive credit toward future Marine Layer purchases. Marine Layer has collected more than half a million tees since its program started.

ChicoBag (asi/44811) says it gets bags from all across the country – some of which aren’t ones it produces – through its take-back program.

Old T-shirts must be sorted for material content (Everywhere uses only 100% recycled cotton in its tees, for example) and any decoration cut out before the garments are shredded and turned into yarn, which can then be transformed into new T-shirts. The cut-out decorations and lower-quality fabric can be downcycled into things like carpet padding, stuffing for plush animals or insulation.

ChicoBag also has a take-back program for any bags, not just the ones it produces, Keller says. The supplier will find new life for the bags – donating them to food banks and other charities – or turn them into things like woven rugs if they’re too damaged to use. Currently, ChicoBag processes hundreds of bags a month through its take-back program, some of which come in bulk, but most arriving in small boxes from around the country, Keller adds.

Everywhere Apparel has facilitated in-person recycling drives as another take-back option. When a brand is about to launch new uniforms or update its logo, executives will invite employees to bring in their old garments to the office for recycling first. “They’ll create a campaign and build excitement around that,” Kornbluth says. “That has worked nicely.”

Focus on Your Own Waste

Savage of Zero Waste Strategies will literally go through her clients’ trash to help them keep material from entering landfills. “We’re dumpster diving up to our elbows,” she quips about the waste audits her consultant firm conducts. “But there’s a method to our madness.”

She’ll go through a representative sample of waste, sorting through each piece, cataloging and weighing it, finding out how much was landfill trash, how much was compostable, how much was recyclable and how much was mishandled or cross-contaminated. Then she can help clients develop a plan to reduce or cancel out landfill-destined refuse.

That’s a step some suppliers have already begun on their own. At the factories Storm Creek works with, Jackson makes sure that every scrap of material on the cutting-room floor is accounted for. “We know where every little square inch went,” he says. “We have people pick up that fabric waste, and it gets recycled again.”

Botanical PaperWorks repurposes off-cuts from its seed paper, turning them into plantable box filler for customers, as an alternative to things like Styrofoam packing peanuts or air-filled plastic packaging. The supplier also launched a new product line, upcycling its used wooden pallets into products like soap dishes and coasters.

Get Smart About Packaging

Packaging, particularly of the single-use plastic variety, is an 82-million-ton problem in the U.S. And by some estimates, 91% of packaging waste ends up in landfills or leaks into the environment.

But promo pros can help solve the problem by taking a more thoughtful approach to packaging. Use packaging made from recycled materials if you can. “A lot of times you’re saving between 30% and 90% of the carbon footprint of that material by using a recycled source,” says Sarah Quirk, sustainable innovation lead at EcoEnclose, a company that offers sustainable packaging materials.

Reuse boxes and mailers when possible. Look for more sustainable eco-fill to protect items. Rethink the need for individually polybagging each item. Everywhere Apparel, for example, uses 100% recycled packaging and has mostly eliminated inner packaging of its garments completely. Occasionally, Kornbluth says, the supplier will put recycled plastic polybags around white T-shirts to protect them from the elements.

“The least sustainable shipment is one that gets damaged in transit,” Quirk agrees.

Remember too that you don’t have to sacrifice style and branding for sustainability. Though white corrugated boxes with full-color ink coverage are typically made of virgin materials, Quirk says there are plenty of options for making unboxing experiences special while using recycled materials and sustainable black algae ink. “We can still have an amazing aesthetic through printing, through tissue paper, through a custom notecard or sticker,” she says, “but it doesn’t have to be at the expense of using virgin tree fiber.”

As someone whose bread and butter is helping organizations launch sustainability initiatives, you might assume Lia Colabello, managing principal of Planet+Purpose Solutions, would be against the very idea of promotional products, dismissing them as “trinkets and trash” the way industry outsiders sometimes do. On the contrary, Colabello places high value on a well-thought-out promotional item.

“You can look at the idea of a promotional product as a gift from your company to a customer. It’s a very meaningful transaction, so what you’re giving shouldn’t be trash or easily disposed of.” Lia Colabello, Planet+Purpose Solutions

“I grew up in Hawaii, and gift-giving is very serious business,” she says. “You can look at the idea of a promotional product as a gift from your company to a customer. It’s a very meaningful transaction, so what you’re giving shouldn’t be trash or easily disposed of. You don’t want that. It’s part of cementing your relationship with people.”

Be Thoughtful About Your Promotions

Colabello says Planet+ Purpose Solutions has two different tiers for its promo purchases. Higher-value, inner-circle clients might receive a branded Yeti tumbler, whereas those in the second tier receive bamboo cutlery from ChicoBag’s To-Go Ware division. Both items fit within the sustainability consultancy’s mission of reducing plastic waste, while still building client goodwill and spreading the company’s marketing message beyond the original recipient.

PacificWRO, a Portland, OR-based design firm, has sourced Rhodia notebooks – the specific brand preferred by its architecture clients – as a thoughtful, targeted promo, rather than blanket all prospects with a lower-quality item.

“One piece of promotional material symbolizes so much,” Colabello says. “That’s why you’ve got to be really thoughtful. It’s not only your original audience, but it’s who they’re interacting with and how they’re looking at your company too.”

Matt Johnson, marketing and communications manager for Portland, OR-based design firm PacificWRO, also takes a strategic approach to promo. For example, his company’s architecture and design clients have a specific brand of high-end paper that they like. “We’ll pay more for a small run of Rhodia notebooks with our logo on it, as opposed to just getting a whole run of junky notebooks we can just pass out to everybody,” Johnson explains. “It’s all about being specialized and focused.”

Source Long-Lasting, High-Quality Items

Turkish towels from the Riviera Towel Company (asi/82647) are kept on average for 10 years, says Albert DiPadova, co-founder of the supplier. They’re made from a premium cotton with extra-long fibers, which results in a smoother thread that’s softer, fluffier and more durable, he notes. The supplier works with artisans in Turkey. “It’s a cottage industry that’s been around for generations,” says DiPadova, whose company made relief donations to Turkey after February’s deadly earthquake. “They hand-tie every tassel on every towel.”

Storm Creek also strives to create garments that endure. “We work so hard to make sure that the garment will last wash after wash,” Jackson says. “We’re the furthest thing from fast fashion. We are such sticklers with our suppliers and the materials that we use. You have to make a good product in our view, and we try to make stuff that lasts.”

Brand Addition tries to steer clients toward quality purchases as part of its sustainability strategy. “We have three product sustainability managers, and they help the buyers and procurement teams to look at the best choices,” Jennings says. So, rather than selling a traditional reusable shopping bag, for instance, the Brand Addition team might suggest a jute tote, which is longer-lasting, but also made in a factory that supports girls’ education in India, giving the client more sustainability bang for their buck, she adds.

Explore All the Re’s, Not Just Recycling

Recycling is an important aspect of the circular economy, but it should be a last resort for an unwanted item, not the first. “Most people think that recycling is where everything is supposed to go,” Savage of Zero Waste Strategies says. “There’s all kinds of reuse and repair that we don’t address. We miss a lot of opportunities.”

She points to one of her clients, Nestle Purina, which has a whole maintenance department to fix things like broken casters on desk chairs. “Nothing really goes out to recycling unless it’s actually, truly exhausted its many lives,” Savage says. “Repairs are a huge cost-saver for them.”

Charitable donations are another key part of reuse strategies. There are a number of distributors who help facilitate donations of unwanted and unusable promo. SwagCycle, an initiative started by Somerville-MA-based distributor Grossman Marketing Group (asi/215205), has kept a cumulative 1.45 million items out of landfills and facilitated around $2.67 million in donations, according to its most recent annual impact report. “It’s been thrilling to see the demand from companies looking to donate or recycle their swag with us, as well as the range of charities who have requested to join our platform,” founder Ben Grossman said in a February annual impact report.

The goal for a circular economy isn’t just to maintain the world as it is, but also to repair the harm that industrialization has wreaked.

“We’re really working to get away from the destructive linear economy and move toward one that’s regenerative,” Savage explains.

“We’re really working to get away from the destructive linear economy and move toward one that’s regenerative.” Stacy Savage, Zero Waste Solutions

Support Environmental Giveback Programs

Products with associated giveback programs are a great way to add an extra layer of meaning to a promotion, something that can be highlighted in the branding story your client tells end-users. Many suppliers work with organizations like 1% for the Planet, committing at least 1% of their annual revenue to causes that protect the environment.

Some take the giving a few steps further. Riviera Towel, for example, has committed 5% of its net profits to go to various ocean conservation organizations that do things like protect sea turtles and restore coral reefs in the Florida Keys. “They were kind of personal choices,” DiPadova says of the charities his company works with. “I grew up in the Keys and wanted to give back. I want to see my water clean. I want to see everybody’s water clean.”

Seek Out Products That Promote Biodiversity

Biodiversity – referring to the variety of life on the planet, from plants to animals to microorganisms – is crucial to the health of our ecosystems. There are plenty of actions you can take in your day-to-day life to help promote biodiversity, whether it’s supporting local farms, planting native flowers and fruits, or respecting local habitats.

Botanical PaperWorks (asi/41273) sources recycled materials to create its custom seed paper, which then gets planted in the ground, leaving no waste.

The types of promotional products you offer clients could also have an impact on biodiversity. Apparel made of certified organic or regenerative cotton doesn’t allow the use of chemicals in farming and can help preserve soil health and protect animal and insect life. Seed-paper suppliers like Botanical PaperWorks can create custom paper using native seeds that can be planted in areas where they would naturally thrive.

Reduce Your Carbon Footprint

You’ve probably seen headlines for larger companies committing to reach net zero or even net negative greenhouse gas emissions by a certain date. Or they’ve set targets to reduce Scope 1 emissions, the direct emissions that come from a facility, whether it’s fuel burned in company vehicles or natural gas used to heat an office; and Scope 2 emissions, which are indirect emissions mostly through things like purchased electricity. Scope 3, indirect emissions from a supply chain, are less discussed but just as important and often make up the majority of a company’s footprint.

Setting such targets is a worthy endeavor, though it can lead to greenwashing if a corporation continues to push its goals further and further into the future. What’s more important, says Keller of ChicoBag, is what a company is “doing right now” to reduce its footprint.

To begin, you need to measure your current impact so you can set a baseline. There are carbon footprint calculators online, but many businesses choose to work with consultant firms to help with this. Once you know where you are, you can work on reducing that number by changing your operating practices and purchasing carbon offsets – essentially paying someone else to cut greenhouse gases by investing in solar or wind energy, planting trees or restoring rainforests – to make up for the rest.

Carbon offsets have received a lot of negative press in recent years, thanks to bad actors in the multibillion-dollar space. The Guardian published an investigation earlier this year that found that more than 90% of the rainforest offset credits sold by carbon standard Verra were likely to be “phantom credits” that don’t represent genuine carbon reductions. There have been other reports of people selling offsets to protect trees that were never under threat of being cut down.

Despite this, Keller still believes offsets are a valid way for companies to reach carbon neutrality, especially when paired with internal reduction efforts. “It’s a market, and there are high-quality carbon offsets, and then there are low-quality ones. The high-quality offsets aren’t necessarily the cheapest ones, right? The key thing is to do your homework and shop wisely,” he adds.

An alternative to offsets, Colabello says, is something called “carbon insetting.” Instead of paying $100,000 to protect trees with an offset, for instance, your business could invest the same amount of money into a solar array, she notes.

Colabello adds: “It’s all a part of this journey toward sustainability.”